replace the lockwire between the filter case and

1

the head assembly.

METAL-TYPE FILTER ELEMENTS.--The

IN

OUT

two most common types of metal filter elements are the

3

sintered bronze and the stainless steel. The sintered

bronze element consists of minute bronze balls joined

together as one solid piece, but it still remains porous.

The process of joining the balls together is known as

the sintered process. Like the micronic filter described

2

previously, filters using the sintered bronze elements

are equipped with a bypass valve. If the element

4

becomes clogged, the bypass valve will open, allowing

t h e f l u i d t o b y p a s s t h e fi l t e r e l e m e n t w h e n a

predetermined pressure differential exists. The

sintered bronze element can be cleaned, tested, and

ASf08022

reused several times. The stainless steel filter element

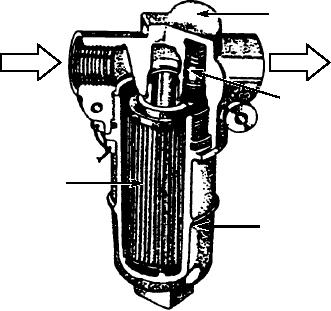

1. Filter head

3. Relief bowl

may be of corrugated, sintered, or mesh construction.

2. Filter element

4. Filter bowl

Figure 8-22.--Full flow, bypass hydraulic filter.

WIRE MESH FILTER ELEMENTS.--A wire

mesh filter element is made of a fine wire mesh

Hydraulic fluid enters the filter assembly through

(screen) and is usually used where the fluid enters

and/or leaves a container or component (view A of

the inlet port in the body and flows around the filter

figure 8-18). The size of wire mesh openings vary with

element inside the filter bowl. Filtering takes place as

the particular filter element, but normally a wire mesh

the fluid passes through the filter element and into the

filter element removes only the larger particles of

hollow core, leaving dirt and impurities deposited on

contamination from the fluid.

the outside of the filter medium. The filtered fluid then

flows from the hollow core, through the outlet port, and

A wire mesh filter element can be reused. It should

be removed, cleaned, and reinstalled at scheduled

continues on through the system.

intervals or when it becomes dirty. Replace it when it

The bypass relief valve in the body allows the fluid

cannot be properly cleaned or is damaged.

to bypass the filter element and pass directly into the

outlet port if the filter element becomes clogged. In

Multiple Filtering Elements

many micronic filters, the relief valve is set to open

when the differential in pressure exceeds 50 psi. For

Normally, only one element is used in each filter;

however, some equipment use two or more elements to

example, if the pressure at the filter inlet port is 90 psi

obtain the desired degree of filtration. In this

and the pressure at the outlet drops below 40 psi, the

arrangement, the filter elements are usually designed

bypass valve opens and allows the liquid to bypass the

so that one fits inside the other. The elements may be of

element.

the same type or of a different type. An example of

equipment that uses this filter arrangement is the

Contamination Indicators

portable hydraulic test stand (in final filtration stage)

used on an aircraft.

Hydraulic systems in support equipment that is

used to service aircraft hydraulic systems use a

Bypass Characteristics

non-bypass filter, so some type of contamination

indicator must be used to prevent damage to the

A full flow, micronic, bypass filter is shown in

hydraulic system if these filters become clogged. A

figure 8-22. This filter provides a positive filtering

pressure switch, connected across the filter to sense the

a c t i o n . H ow eve r, i t o ff e r s r e s i s t a n c e t o f l ow,

pressure differential, actuates at a preset pressure

particularly when the element becomes dirty. For this

(usually 100 psi) and causes a warning device to

reason, a full flow filter usually contains a bypass

operate; this indicates that the filter is clogged. The

valve, which automatically opens to allow the fluid to

warning device may be a button popping up on the

bypass the element when the flow of fluid is restricted

because of contamination buildup on the element.

filter or control panel, a warning light illuminating at

8-18