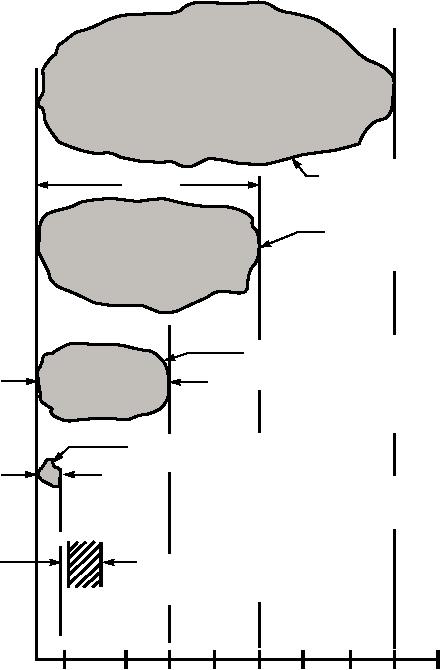

SMALLEST PARTICLE THAT

0.001 INCH

CAN BE SEEN BY UNAIDED

EYE (APPROX. 40 MICRONS)

LARGEST PARTICLE PASSED

BY OLDER TYPE WIRE MESH

FILTERS

LARGEST PARTICLE PASSED

BY PRESENT TYPE WIRE

MESH FILTERS

LARGEST PARTICLE PASSED

BY MODERN SE FILTER

1 MICRON = 1 MILLIONTH OF A METER (1 METER x 10-6 )

1 MICRON = 39 MILLIONTHS OF AN INCH

1 INCH = 25,400 MICRONS

APPROX. CLEARANCE

FOR SLEEVE / SLIDER

SERVO VALVES

0

3

10

20

30

40

ASf08020

Figure 8-20.--Graphic comparison of particle sizes.

A typical micronic filter is shown in figure 8-21.

support equipment. This type filter is still in use but is

not specified in newer equipment.

This type of filter is designed to remove 99 percent of

all particles 10 microns (0.00394 inch) in diameter and

The micronic filter assembly contains an integral

larger. The following discussion will help you to define

bypass valve to prevent possible element collapse or

this capability in meaningful terms: If 100 particles

system starvation. If the micronic filter element

measuring 0.000394 inch in cross section were

becomes loaded, the bypass valve will open when a

dropped into pure hydraulic fluid, a 10-micron filter

predetermined pressure differential exists, allowing

hydraulic fluid to bypass the filter element.

will intercept 99 percent of these in one pass. A

40-micron particle is regarded to be the smallest that

The replacement element is made of specially

can be seen without magnification. A micronic filter

treated cellulose paper, formed in vertical convolutions

assembly contains a replaceable micronic filter

(wrinkles). Generally, the micronic filter element

element and, in some cases, an integral pressure

slides onto the head and is held secure by the filter

differential bypass valve. The micronic filter was first

bowl, which has external threads machined on the

outside and top. A groove machined around the base of

procured in the 1950's and widely used in aircraft and

8-16