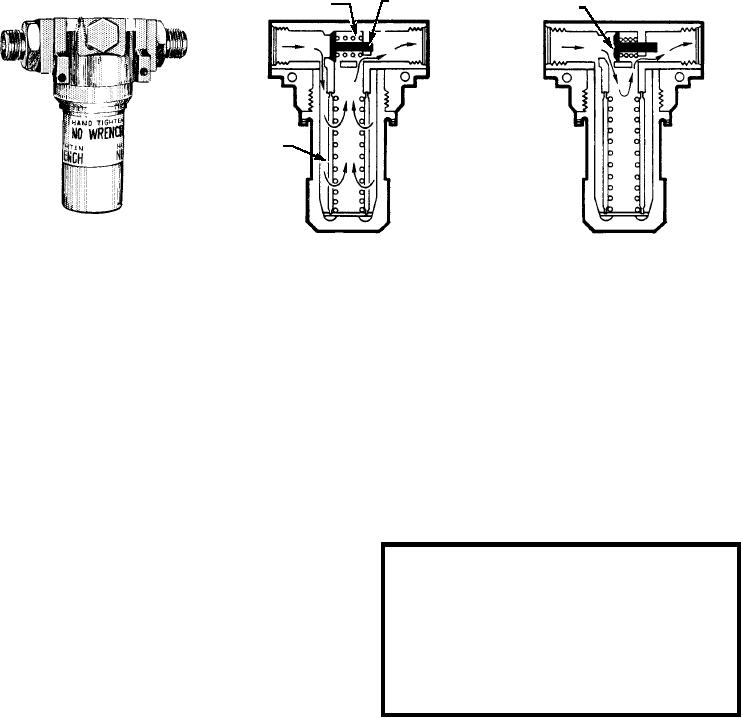

RELIEF

RELIEF VALVE OPENED

RELIEF

VALVE

BY DIFFERENTIAL

VALVE

SPRING

PRESSURE

IN

IN

OUT

OUT

FILTER

ELEMENT

ASf08021

CLOGGED FILTER

NORMAL LOW

ELEMENT

Figure 8-21.--Micronic filter.

4. The filter element shown in figure 8-19 is

the threads provides the location for packing between

removed from the case by extracting the

the filter bowl and body assembly.

retaining ring and removing the filter element.

Fluid enters the filter through the inlet port in the

NOTE: At the time of filter element replacement,

body and flows around the element inside the filter

you should never try to gauge its condition by visual

bowl. Filtering takes place as the fluid passes through

inspection alone. The naked eye cannot detect particles

the filtering element at the hollow core, leaving the dirt

smaller than 40 microns. Consequently, the element

and impurities on the outside of the filter element.

could be heavily contaminated with 10- to 20-micron

Filtered fluid then flows from the hollow core to the

particles, and the only way the condition of this

outlet port in the body and into the system.

element can be determined is by performing a back

pressure flow check on a test stand.

The bypass pressure-relief valve in the body

allows fluid to bypass the filter element and pass

directly through the outlet port in case the filter

CAUTION

element becomes clogged. In most filters of this type,

When selecting a new filter element, do not be

the relief valve is set to open if the pressure differential

guided by its appearance and physical dimensions

exceeds 50 psi. In other words, if the pressure at the

alone. Always go by the part number. Many

filter inlet port was 1,500 psi and the pressure at the

elements look identical but will disintegrate if

outlet port dropped below 1,450 psi, the relief valve

installed in the wrong type of fluid; this will cause a

would open.

good hydraulic system to become contaminated.

NOTE: Some filters of this type are not equipped

with this type of bypass pressure-relief valve.

5. Prior to installation of the replacement element,

Micronic filter elements are replaced with new

the filter head and filter case must be cleaned

filter elements at regular intervals. These intervals are

and inspected for damage. All damaged parts

specified in the applicable MIM and maintenance

must be replaced.

requirements cards (MRCs). The following procedure

6. Replace all O-ring seals.

for removing and replacing filter elements is typical of

7. Fill the filter case, if practical, one-half full of

almost all systems:

hydraulic fluid, and install the filter element in

1. Relieve system pressure.

its case and screw the case into the filter head.

2. Cut the lockwire and remove the filter case

The correct torque is usually handtight or

(bowl) from the filter head (body).

handtight plus one-eighth turn. Always check

the specific MIM.

3. Unscrew and remove the filter case, using a

slight rocking and downward pull on the case

8. Pressurize the system and inspect the filter

after the case threads are free from the filter.

assembly for leaks. If it is found satisfactory,

8-17