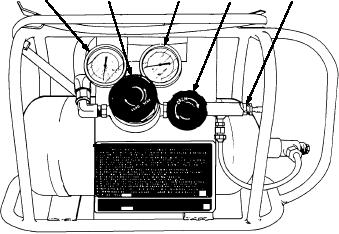

CYLINDER

DELIVERY

Q9-3. How is nitrogen obtained on an aircraft

PRESSURE SHUT-OFF

PRESSURE

RECHARGE

PRESSURE

GAUGE

REGULATOR

VALVE

VALVE

GAUGE

carrier?

1. It is manufactured by using a

nitrogen-condensing pump

2. It is purchased and stored by the supply

department

3. It is a by-product of oxygen production

4. It is manufactured by using a nitrogen

Q9-4. A nitrogen bottle containing oil-tolerant

nitrogen has which of the following paint

schemes?

AMf09002

1.

A gray bottle with one black band

Figure 9-2.--Portable high-pressure nitrogen cylinder.

2.

A gray bottle with two black bands

3.

A gray bottle with three black bands

identification of the contents is printed in white on the

4.

A gray bottle with no bands

cylinder. The cylinder's last hydrostatic test date is also

stenciled across the bottom of the cylinder.

Q9-5. Which type of nitrogen should NEVER be

used to purge an oxygen system?

Components

1.

Class 1

2.

Class 2

The components of the walk-around bottle are

3.

Class 3

mounted on a one-piece welded frame designed to be

4.

Class 4

hand-carried. The cylinder assembly is fastened to the

bed of the frame by means of two quick-coupling

PNEUMATIC-TYPE SUPPORT

clamps, which provide fast removal and installation of

EQUIPMENT

the cylinder. The pressure regulator is bolted to the

front of the frame, and all other servicing parts are

LEARNING OBJECTIVES: Identify the

attached to the regulator.

components of pneumatic systems. Identify

The top of the frame has four brackets for coiling

procedures for inspecting, troubleshooting, and

the servicing hose when it is not in use. The major

repairing pneumatic systems and related

components are the cylinder, the shutoff valve, the

components.

pressure regulator, the cylinder pressure gauge, the

delivery pressure gauge, the bleed valve, the servicing

The portable high-pressure nitrogen cylinder

hose, and the recharge valve.

(commonly called a walk-around bottle) and the

CYLINDER.--The nitrogen cylinder is a

A/M26U-4 nitrogen servicing unit are typical of

nitrogen servicing equipment currently in use by the

500-cubic-inch capacity reservoir designed for a

Navy. We will also briefly cover low-pressure air

working pressure of 3,000 psi. It is shatterproof and

contains a safety disc that is designed to burst between

4,000 to 4,500 psi to prevent over pressurizing the

PORTABLE NITROGEN CYLINDERS

cylinder during recharge.

SHUTOFF VALVE.--The shutoff valve controls

The walk-around bottle, shown in figure 9-2, is

the flow of nitrogen from the cylinder to the inlet of the

designed for hand carrying to remote locations for

regulator. It is a needle valve that is open only during

charging such components as accumulators, aircraft

servicing operations. The valve is closed when the unit

struts, and high-pressure tires. The user can control

is stored or the cylinder is being recharged.

delivery pressure up to a maximum of 3,000 psi.

PRESSURE REGULATOR.--The pressure

Nitrogen cylinders are painted gray with black

regulator is a single-stage assembly that allows the

stripes. One black stripe identifies oil-pumped

operator to set the delivery pressure. Once the delivery

nitrogen, and two black stripes identify water-pumped

nitrogen. In addition to the color codes, the exact

pressure is set, the regulator maintains this pressure as

9-3