R1

R2

G1

G2

G3

G4

5

2

1

4

3

6

20

CYLINDER ARRANGEMENT

12

21

3

19

16

26

25

11

9

28

4/5

GREEN

GREEN

29

RED

7

8

21

5

15

18

10

RELIEF

VALVE

SYSTEM

CHARGING

29

29

22

27

2

1

24

14 17

23

13

CYLINDER RECHARGING

AIRCRAFT SYSTEM CHARGING

ASf0906

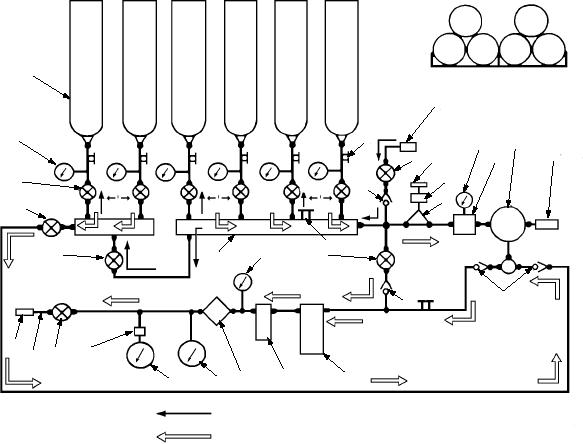

Servicing line

Pressure gauge, 0-200 psi (motor inlet)

1.

16.

Servicing line valve

Pressure regulator

2.

17.

Cylinder pressure gauges (6 each)

Manifold assembly

3.

18.

Lever control valves (green) (4 each)

Motor and pump

4.

19.

Lever control valves (red) (2 each)

Nitrogen storage cylinders (6 each)

5.

20.

Manifold bypass valve

Frangible safety discs (7 each)

6.

21.

Motor inlet selectro valve

Servicing line connection

7.

22.

Pump inlet valve

Filter

8.

23.

Recharge valve

Purifier

9.

24.

Manifold shutoff valve

Motor regulator

10.

25.

External air connection

11.

26.

Recharge connection

Low-pressure gauge cutout

12.

27.

Pressure gauge, 0-600 psi (low pressure)

Filter (inlet-air)

13.

28.

Pressure gauge, 0-5,000 psi (high pressure)

Check valve

14.

29.

Pressure gauge, 0-5,000 psi (manifold pressure)

15.

Figure 9-6.--A/M26U-4 system nitrogen flow diagram.

NITROGEN CYLINDERS.--The nitrogen

CONTROL PANEL.--The control panel, figure

cylinders (20) store the supply of nitrogen for the unit.

9-5, mounts the necessary valves, gauges, and

They are mounted horizontally and held in place by

plumbing components to operate the nitrogen

straps, as shown in figure 9-4. The cylinders are gray

servicing unit. The valves (4 through 10 and 17),

with two black bands, indicating that they contain

gauges (3 and 13 through 16), and plumbing

oil-free (formerly water-pumped) nitrogen. Note that

components direct the flow and control the pressure of

the cylinders do not have cutoff valves in the neck, as

nitrogen throughout the servicing system. A motor and

do most other cylinders. For this reason, you cannot

pump assembly (commonly referred to as a booster

install full cylinders on this unit; the cylinders must be

installed empty and charged in place. Nitrogen

pump), a motor regulator, a purifier, and a filter are

pressure in all cylinders should be maintained between

attached to the back of the control panel. (Only a part of

200 and 3,500 psi. The gaseous nitrogen used in this

the motor and pump assembly is shown in figure 9-5.)

system is Federal Specification BB-N-411, Type 1

NOTE: The number in parenthesis following the

(gaseous), Class 1 (oil-free), Grade B (99.50 percent

pure, low-moisture content).

component name refers to figures 9-5 and/or 9-6.

9-8