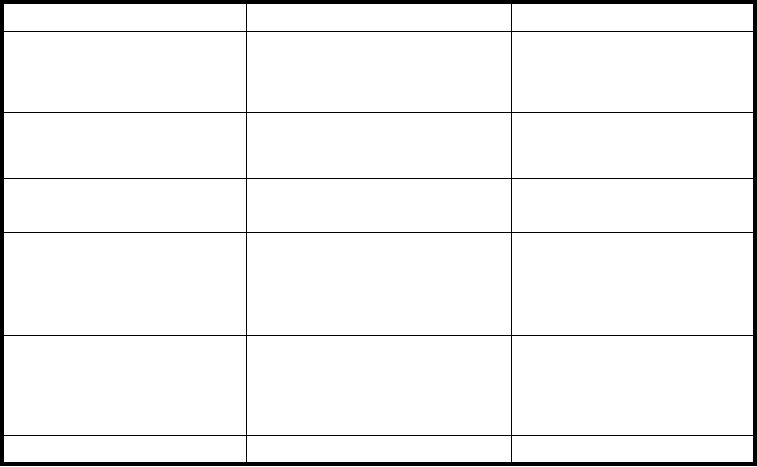

Table 9-1.--Portable High-Pressure Nitrogen Cylinder Troubleshooting Chart

Trouble

Probable Cause

Remedy

Recharge cylinder

With shutoff valve open, cylinder

Cylinder completely discharged

pressure gauge reads zero

Replace safety disc

Cylinder safety disc blown

Replace shutoff valve

Shutoff valve defective

With shutoff valve open and

Gas leaking

Locate and repair leak

pressure regulator set to zero,

cylinder loses pressure

Regulator control has no effect on

Delivery pressure gauge defective

Replace delivery pressure gauge

delivery pressure gauge reading

Regulator defective

Replace regulator

Unit does not charge an external

Hose valve in BLEED position

Rotate hose valve to FLOW

system during charging operation

position

Replace hose valve

Hose valve defective

Servicing hose defective

Replace servicing hose

Replace recharge valve

Cylinder does not pressurize

Recharge valve defective

during recharging operation

Replace safety disc

Safety disc blown

Shutoff valve regulator and hose valve Close shutoff valve, regulator, and

hose valve

are open

Cylinder is loose in its mounting

Cylinder clamp loose

Tighten cylinder clamp

water-pumped nitrogen with compressed air or

discussed in detail in the following paragraphs. The

oil-pumped nitrogen.

A/M26U-4, shown in figure 9-4, is typical of other

nitrogen servicing trailers you might encounter, and

Do not charge this system with oxygen or

most of what you will learn about it applies to the other

interchange components with oxygen

trailers.

components. To do so may cause an explosion.

The A/M26U-4 has a welded frame assembly

Never charge systems at higher than prescribed

mounted on a two-wheel axle and a retractable swivel

pressures.

caster front wheel. The compressed gas cylinders are

Always close the regulator after use to prevent

mounted to the frame in two groups of three.

accidental over-pressurization during

A drawbar coupler ring on the front of the frame

subsequent charging operations.

assembly allows the equipment to be towed by a

Because of the high pressure used in this system,

vehicle that is equipped with a pintle assembly.

do not, under any circumstances, interchange

A hand-operated, mechanical brake is used to

components of this system with parts from other

systems.

secure the cart while it is stationary. The brake system

uses a cable linkage connected to a cam, which is

Release all pressure from the nitrogen cylinder

located on the wheel backplate.

before disconnecting any tubing.

Components

NITROGEN SERVICING TRAILERS

Figure 9-5 is a view of the control panel of the

Nitrogen servicing trailers provide a mobile source

trailer, and figure 9-6 is a system nitrogen flow

of high- and low-pressure nitrogen for servicing

diagram. The numbers inserted in parentheses in the

aircraft high-pressure systems and for inflating tires.

text are to help you locate the various components in

The nitrogen servicing trailer most widely used in the

the figures.

fleet is the A/M26U-4 nitrogen servicing unit. It is

9-6