operation. The newer type regulator is designed to

If the regulator is not stripped (the most common

prevent such an occurrence. Repair kits are available

cause for failure), turn the handle counterclockwise to

for both types of regulators and should be installed in

relieve pressure on the spring and relieve any internal

accordance with AG-750AO-OMM-000. A parts

pressure. Loosen the connections slowly, so that any

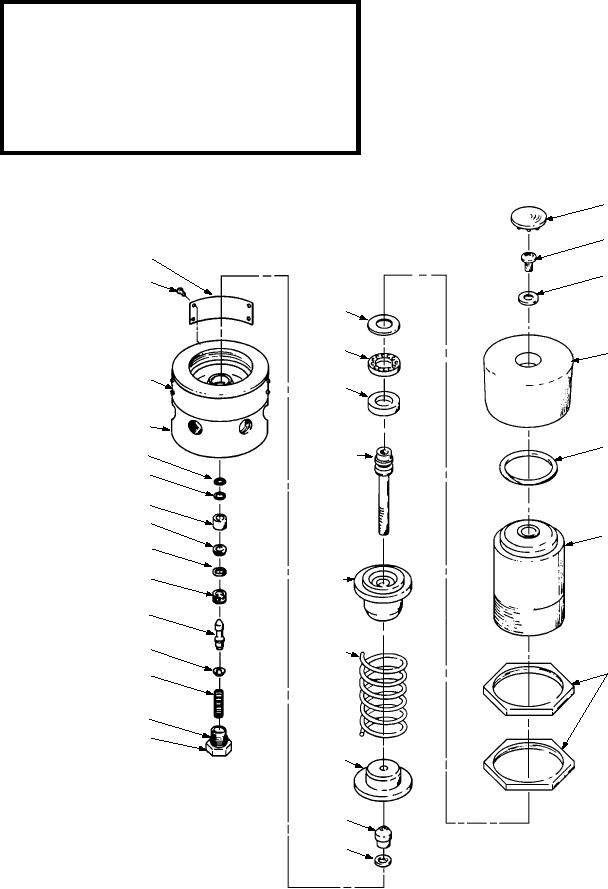

breakdown of a regulator is shown in figure 9-9.

pressure in the system will bleed off slowly. When all

the gauges read zero and you hear no further bleed-off

WARNING

noise, disconnect the lines from the unit to the

regulator. Then, remove the regulator and place it on a

Always be sure to release all pressure from the six

clean workbench for repair. After reassembly, perform

nitrogen cylinders before disconnecting any

tubing. Failure to do so may lead to accidental

a pressure check. Use leak detection compound,

discharge of high-pressure nitrogen with possible

MIL-L-25567, to check for leaking.

severe injuries to personnel.

FILTERS AND PURIFIERS.--Filters and

purifiers are normally changed in accordance with

periodic maintenance requirements. At times,

PLUG

BUTTON

SCREW

NAME

PLATE

WASHER

SCREW

RACE*

ROLLER*

HANDLE

NAME

PLATE

RACE*

BODY

SCREW

O-RING*

ADJUSTING*

O-RING*

WASHER*

FILTER

SEAT*

HOUSING

O-RING*

SLEEVE

ASSEMBLY

DRIVE*

CAGE

STEAM*

WASHER

SPRING

JAM

SPRING

NUT

O-RING*

RETAINER

SUPPORT

PISTON*

O-RING*

* ITEMS INCLUDED IN PARTS KIT

ASf0909

Figure 9-9.--Pressure regulator assembly.

9-15