however, they may become contaminated or burst and

After installing a new filter and purifier cartridge,

need to be changed early.

you should charge the nitrogen servicing cart and

check for leaks with leak detection compound.

CAUTION

VALVES AND OTHER COMPONENTS.--

Most valves on the nitrogen servicing unit are

Relieve all pressure from the nitrogen cylinders

considered not repairable; however, you may have to

before disconnecting any tubing and before

clean them with an approved cleaning solvent to

removing the filter element or purifier cartridge of

improve their functionality until a new replacement

desiccants. Disassemble only to the extent

item can be obtained.

necessary for replacing defective components.

CAUTION

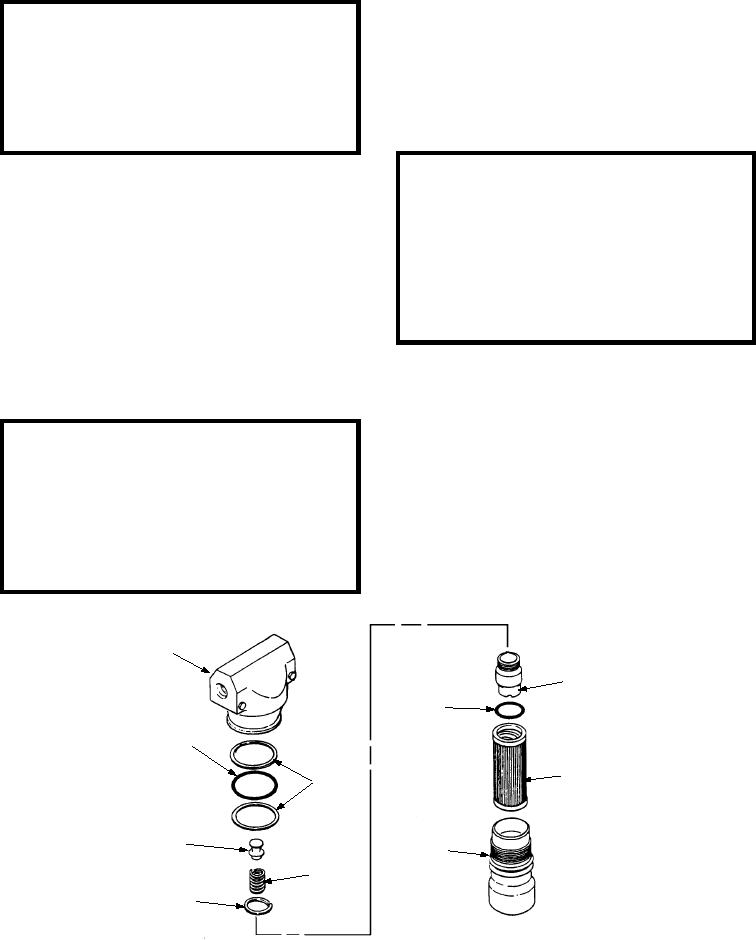

Changing The Filter.--The filter, shown in figure

Do not allow dry-cleaning solvent to contact

9-10, can be removed by unscrewing the bowl and

rubber parts, as this causes rubber to deteriorate.

pulling it down. When installing a new filter, install a

Clean all metal parts with dry-cleaning solvent or

new O-ring in the bowl. Be careful not to overtighten

carbon tetrachloride. Remove hard crust and minor

the bowl. It is the O-ring that makes the seal, not the

corrosion with a bristle brush dipped in

tightness of the bowl.

dry-cleaning solvent. Then, wipe dry with a clean,

Changing The Purifier Cartridge.--When

lint-free cloth or dry with compressed air.

changing the purifier cartridge, shown in figure 9-11,

ensure that all pressure is relieved in the system and

Cracked lines are a common problem, and nuts

that all cylinder valves are closed. Replace all O-rings

often become corroded. After valves have been

at the time of cartridge replacement.

repeatedly opened too fast, a burst of high-pressure

nitrogen may cause a device to fail from the surge in

WARNING

pressure. Extreme cold or heat can also take a toll.

Never attempt to remove or install a purifier

Oddly enough, the most severe source of heat isn't the

cartridge until the unit is properly secured and the

sun, but jet exhaust. Occasionally, taxiing jet aircraft

components are relieved of pressure. Gases under

will stop in a position where the jet exhaust is pointing

high pressure, such as are encountered in this

toward a servicing cart. The rapid expansion of metal

equipment, are extremely dangerous to both

due to heating may cause a crack to develop.

personnel and equipment if improperly handled.

NOTE: Fluid Power, NAVEDTRA 14105,

contains a detailed discussion on the fundamentals of

HEAD

NIPPLE

O-RING

O-RING

ELEMENT

BACKUP

RING

VALVE

BOWL

SPRING

LOCK

WASHER

ASf09010

Figure 9-10.--Filter assembly.

9-16