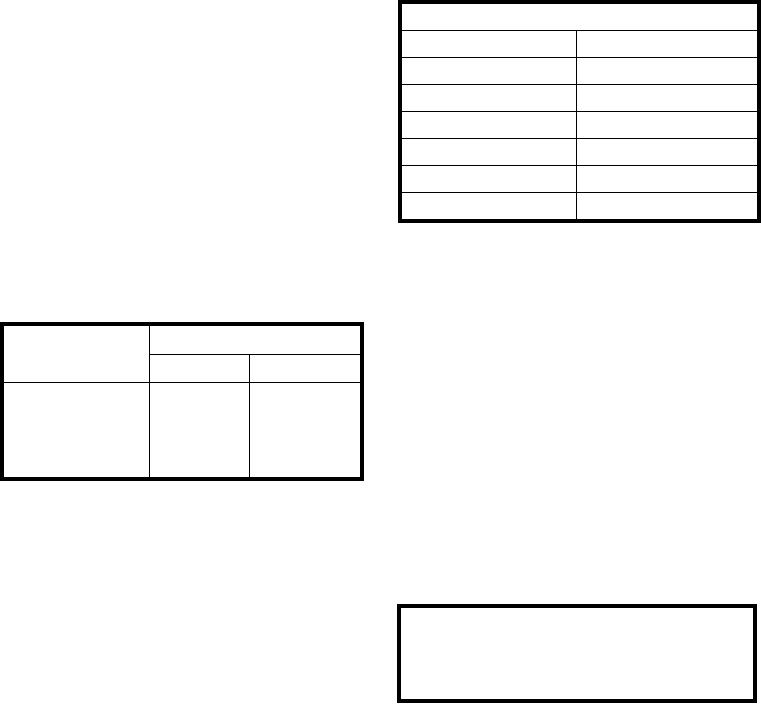

Table 2-3.--Torque Ranges by Bolt Size

A damaged or deteriorated inner tube

FINE THREAD SERIES

After the cause of the leak is corrected, inflate the

tire.

Bolt Size

Torque (lbs in.)

I N S TA L L I N G T H E W H E E L O N T H E

5/16 - 24

100 - 140

VEHICLE.--When wheels are to be used on dual

3/8 - 24

160 - 190

installations, they should be matched in size and tread

7/16 - 20

450 - 500

wear. Improperly matched tires cause rapid, uneven

wear, and may also cause transfer case and differential

1/2 - 20

480 - 690

failures.

9/16 - 18

800 - 1000

If dual tires are used in a situation where

5/8 - 18

1100 -1300

permissible differences in measurement are allowed,

the larger tire should be mounted outboard. Table 2-2

5. Attach the gauge to the remote controller.

lists some instances where differences in measurement

are allowed.

Ensure that the relief pressure valve setting of

the remote controller is no higher than

Table 2-2.--Tolerances in Matching Dual Tires

necessary.

Outside Diameter

Permissible Difference

6. Connect the servicing hose and shop air to the

of Tire

remote controller.

Diameter

Circumference

7. Inflate the tire to the prescribed service pressure.

Under 30 inches

3/4 inch

1/4 inch

Use short bursts to allow frequent pressure

1-1/8 inch

3/8 inch

From 30 to 40 inches

checks.

1-1/2 inch

1/2 inch

From 40 to 50 inches

1-3/4 inch

3/4 inch

Over 50 inche

8. Remove the fitting and valve adapter, and install

the valve cap, finger tight.

Use the following steps for installing a wheel on a

9. Loosen the tie-downs, and jack the vehicle

vehicle:

enough to remove the jack stands. Lower the

1. Ensure that the vehicle is firmly supported on

vehicle, remove the jack, and retighten the

jack stands and chocked. (For our discussion,

tie-downs.

assume that you are aboard ship, and tie-down

chains are required.)

WARNING

2. Place the wheel on the vehicle.

When inflating a tire outside of a safety cage,

Install single wheels with the demountable

ensure that all personnel are clear of the rim/tire

flange outboard.

trajectory area.

For dual wheel assemblies, mount the inner

NOTE: We elected to base our discussion here on

wheel with the demountable flange facing

the demountable flange rim because it is potentially the

outboard. Install a spacer and then the outer

most dangerous to work with. However, the procedures

wheel. For the outer wheel, the demountable

for working with solid and split rims is very similar.

flange faces inboard.

Consult NAVAIR 17-1-129 and other applicable

technical manuals for procedures for working with

3. Install the wheel bolts/clips. Use a crisscross

these types of rims.

pattern, and apply the correct amount of torque.

When torque values are not listed in the

Repairing Wheels by Welding

technical manual or MRC, use the values listed

in table 2-3.

Wheels should be repaired by welding only when

NOTE: Threads should not be oiled, as the torque

new wheels are not available. Such repairs are limited

values listed are derived with oil-free threads.

to one weld of a crack that is no longer than 1 inch, or

4. Install the tire valve adapter to the valve stem,

two welds of cracks that are no longer than 1/2 inch.

and connect the fitting to the adapter.

Further, no weld can be within 1 inch of any bolt hole.

2-85