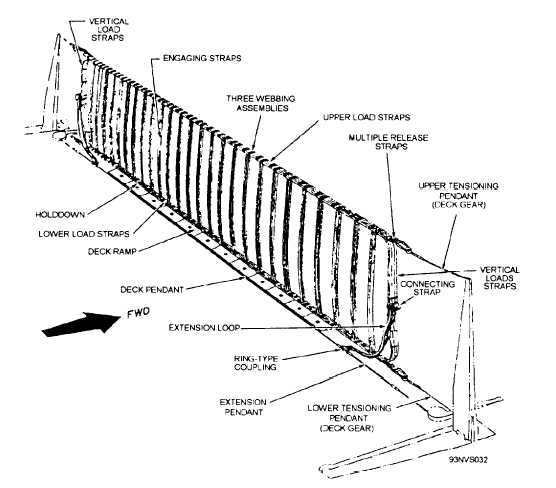

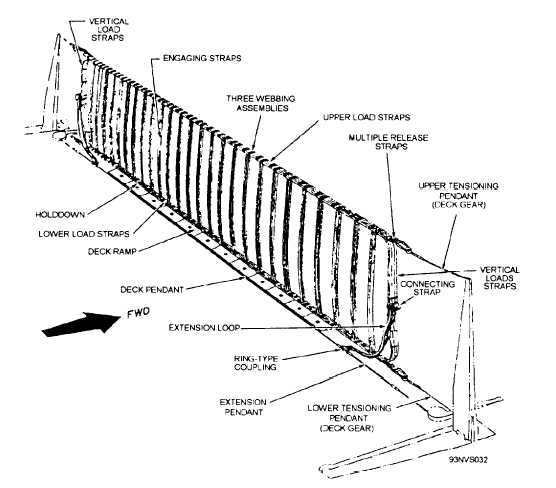

Figure 3-32.—Barricade installation.

wings and wrap about the aircraft (fig. 3-33). The

barricade installation then passes the force of

arrestment through the purchase cable to the

arresting engine. After arrestment, the barricade

and attached hardware arc discarded.

Currently, there are two types of barricades

(each has two configurations) available to the fleet.

Both types consist of three main all-nylon webbing

assemblies, placed one on top of the other and

bundled together to make up one barricade

installation (see fig. 3-32).

The first type or “standard” barricade webbing

assembly consists of five separate webbing systems

to make one main webbing assembly. The new

polyurethane semicoated barricade uses three

separate webbing systems to make one main

webbing assembly. Other differences between the

two types of barricade installations exist and will be

discussed as the need arises.

Each webbing system is composed of upper and

lower horizontal load straps (see fig. 3-32) joined

together at the ends by D-ring link assemblies on

the standard barricade and all-nylon velcro tie-down

straps on the semicoated barricade. (The rolled

edges of the upper and lower load straps of the

semicoated barricade are coated with polyurethane

to reduce wear and damage caused when the

barricade is dragged into position for use.)

Five vertical engaging straps, spaced 20 feet

apart, are connected to each upper and lower load

strap of each webbing system by means of sliding

fittings or loops in the end of each engaging strap.

The 20-foot load spacing between the vertical

engaging straps affords equalized loading of the

barricade during arrestment.

One webbing

assembly, which is either five standard or three

semicoated webbing systems combined, effects

equalized loading every 4 feet along the wing’s

leading edge because of the staggered arrangement

of the vertical engaging straps.

3-36