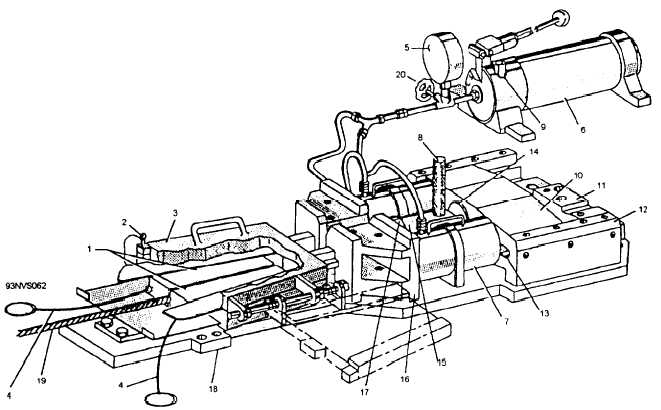

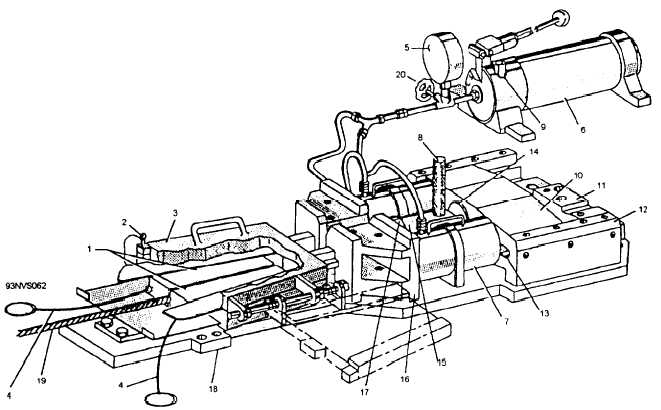

1. Wedge set

2. Safety lock pin

3. Lid

4. Retracting cables

5. Tension gauge

6. Hydraulic pump

7. Ram

8. Pin

9. Selector valve

10. Crosshead

11. Crosshead stop

12. Rail support

13. Rail

14. Crosshead terminal

15. Clevis socket

16. Strongback

17. Cable terminal

18. Base plate

19. Cable

20. Choker valve

21. External load release valve

Figure 3-62.—Wedge-type proof-loading machine (dual ram).

7. Screw the clevis socket on the cable

terminal.

8. Place the cable between the wedges and

connect the clevis socket to the crosshead terminal

with the pin.

9. Manually move the crosshead into the rams,

making certain that the adapter attached to each

end of the ram engages its respective guide hole in

the face of the crosshead.

10. Release the wedges, close the lid, and insert

the safety lock pin.

11. Using chalk, masking tape, or some other

means, mark the cable a measured distance from

the wedge set. This procedure provides a means for

checking cable slippage while the system is being

pressurized.

12. Visually inspect

the socket tester to

make certain that all components are securely

attached.

CAUTION

Do not open the choker valve during

operation of the hand pump, as this will

‘result in excessive pressurization of the

3-62