5. Record the temperature at the freeze point

(solidification) of the zinc. Solidification has

occurred when the temperature-sensitive element of

the pyrometer cannot be removed from the zinc.

6. For the pyrometer to be accurate, the

temperature recorded at the zinc freeze point must

not be greater than 798°F or less than 778°F.

7. Reheat the pouring ladle to remove the

temperature-sensitive element of the pyrometer

from the zinc.

PYROMETERS THAT DO NOT MEET

T H E S E R E Q U I R E M E N T S M U S T B E

REPLACED.

Measure the temperature of the molten zinc by

holding the portable pyrometer in one hand and

dipping the iron tube of the portable pyrometer in

the molten zinc, being sure to keep the

thermocouple in the center of the molten zinc and

not touching the bottom of the pot.

The

temperature of the molten zinc will then be

indicated on the portable pyrometer dial. Pour zinc

at a temperature of 950 to 1,000°F.

Pour the zinc into the terminal. Fill it to within

1/2 inch from the top of the textile cloth to provide

a sufficient “hot top.”

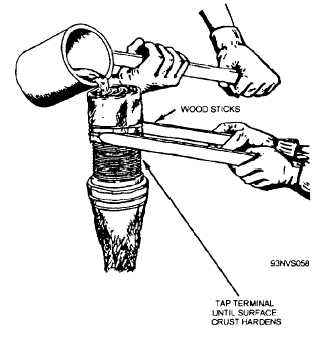

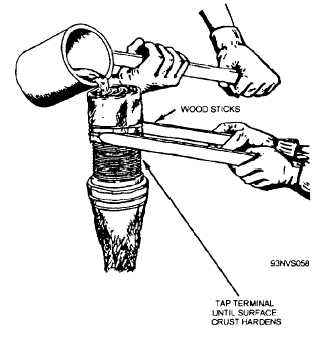

Tap the sides of the terminal lightly with

wooden sticks during and after pouring of the zinc,

until a surface crust forms. See figure 3-58.

Using a short piece of seizing wire thoroughly

degreased, pierce the bubbles that rise to the

surface of the hot top. Do not poke the wire into

the zinc more than 1/2 inch. Skim the surface of

the hot top with the end of the seizing wire to allow

the gas bubbles to rise and be accessible for

piercing.

After the zinc has solidified, allow the poured

terminal to air-cool at room temperature for 30

minutes.

During this time the zinc will harden.

After the cooling period, proceed as follows:

1. Remove the textile cloth and plaster from

the terminal.

2. Pour 4 gallons of preservative oil into a

clean 5-gallon metal container.

3.

With

the

preservative

oil

at

room

temperature, immerse the entire poured terminal for

30 minutes. This will rapidly cool the terminal.

4. Immediately after the 30-minute oil quench

period, remove the terminal and allow the excess oil

to drain into the container.

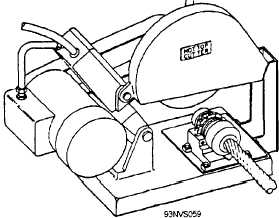

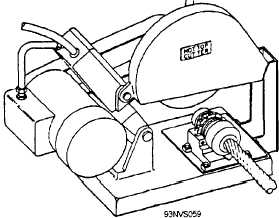

5. Using the hot-top cutter assembly, cut off

the hot top flush with the top of the terminal after

the terminal has cooled (fig. 3-59).

Figure 3-58.—Tapping the terminal during pouring.

Figure 3-59.—Cutting the hot top.

3-59