The type of chisel most commonly used is the flat

cold chisel, which serves to cut rivets, split nuts, chip

castings, and thin metal sheets. The cape chisel is

used for special jobs like cutting keyways, narrow

grooves, and square corners. Round-nose chisels

make circular grooves and chip inside corners with a

fillet. Finally, the diamond-point is used for cutting

V-grooves and sharp comers.

As with other tools there is a correct technique

for using a chisel. Select a chisel that is large enough

for the job. Be sure to use a hammer that matches the

chisel; that is, the larger the chisel, the heavier the

hammer. A heavy chisel will absorb the blows of a

light hammer and will do virtually no cutting.

As a general rule, hold the chisel in the left hand

with the thumb and first finger about 1-inch from the

top. It should be held steadily but not tightly. The

finger muscles should be relaxed, so if the hammer

strikes the hand it will permit the hand to slide down

the tool and lessen the effect of the blow. Keep the

eyes on the cutting edge of the chisel, not on the

head, and swing the hammer in the same plane as

the body of the chisel. If you have a lot of chiseling to

do, slide a piece of rubber hose over the chisel. This

will lessen the shock to your hand.

When using a chisel for chipping, always wear

goggles to protect your eyes. If other personnel are

working close by, ensure they are protected from

flying chips by erecting a screen or shield to contain

the chips. Remember that the time to take these

precautions is before you start the job.

FILES

A toolkit for nearly every rating in the Navy is

not complete unless it contains an assortment of files.

There are several different types of files in common

use, and each type may range in length from 3 to 18

inches.

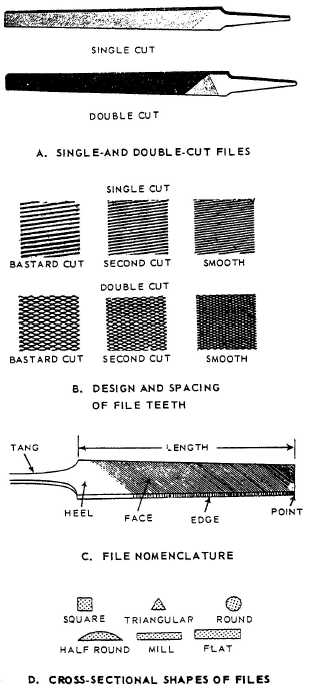

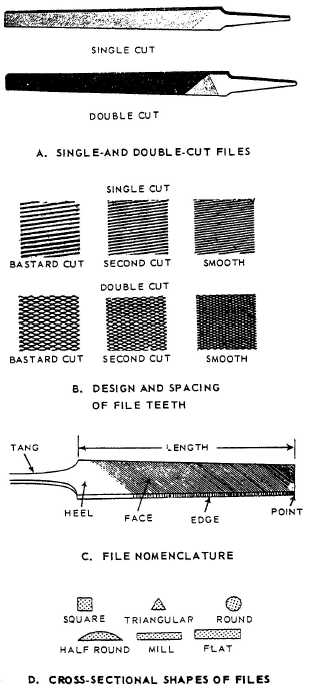

Grades

Files are graded according to the degree of

fineness and according to whether they have single or

double-cut teeth. The difference is apparent when you

compare the files in figure 2-8, view A.

Single-cut files have rows of teeth cut parallel to each

other. These teeth are set at an angle of about 65

degrees with the center line. You will use single-cut

files for sharpening tools, finish filing, and

drawfiling. They also are the best tools for smoothing

the edges of sheet metal.

Files with crisscrossed rows of teeth are double-

cut files. The double cut forms teeth that are

diamond-shaped and fast cutting. You

will use

double-cut files for quick removal of metal and for

rough work.

Figure 2-8.—File descriptions.

2-6