Files are also graded according to the spacing and

size of their teeth, or their coarseness and fineness.

Some of these grades are pictured in figure 2-8, view

B. In addition to the three grades shown, you may use

some DEAD SMOOTH files, which have very fine

teeth, and some ROUGH files with very coarse teeth.

The fineness or coarseness of file teeth is also influ-

enced by the length of the file. The length of a file

is the distance from the tip to the heel, and does

not include the tang (fig. 2-8, view C). When you have

a chance, compare the actual size of the teeth of a

6-inch, single-cut smooth file and a 12-inch, single-cut

smooth file. You will notice the 6-inch file has more

teeth per inch than the 12-inch file.

Shapes

Files come in different shapes. Therefore, in se-

lecting a file for a job, the shape of the finished work

must be considered. Some of the cross-sectional

shapes are shown in figure 2-8, view D.

TRIANGULAR files are tapered (longitudinally)

on all three sides. They are used to file acute internal

angles and to clear out square comers. Special trian-

gular files are used to file saw teeth.

MILL files are tapered in both width and thick-

ness. One edge has no teeth and is known as a SAFE

EDGE. Mill files are used for smoothing lathe work,

drawfiling, and other fine, precision work. Mill files

are always single-cut.

FLAT files are general-purpose files and may be

either single- or double-cut. They are tapered in width

and thickness. HARD files, not shown, are somewhat

thicker than flat files. They taper slightly in thickness,

but their edges are parallel.

The flat or hard files most often used are the

double-cut for rough work and the single-cut, smooth

file for finish work.

SQUARE files are tapered on all four sides and

are used to enlarge rectangular-shaped holes and

slots. ROUND files serve the same purpose for round

openings. Small, round files are often called “rattail”

files.

The HALF ROUND file is a general-purpose tool.

The rounded side is used for curved surfaces and the

flat face on flat surfaces. When you file an inside

curve use a round or half round file whose curve most

nearly matches the curve of the work.

Kits of small files, often called Swiss pattern or

jewelers files, are used to fit parts of delicate mecha-

nisms and for filing work on instruments. Handle

these small files carefully because they break easily.

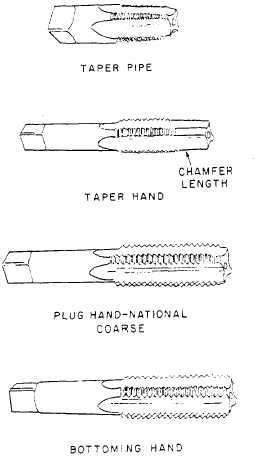

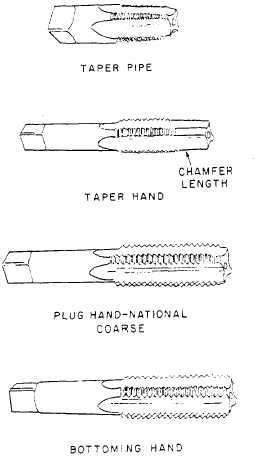

TAPS AND DIES

Taps and dies are used to cut threads in metal,

plastics, or hard rubber. The taps are used for cutting

internal threads, and the dies are used to cut external

threads. There are many different types of taps.

However, the most common are the taper, plug, bot-

toming, and pipe taps (fig. 2-9).

The taper (starting) hand tap has a chamfer length

of 8 to 10 threads. These taps are used when starting

a tapping operation and when tapping through boles.

Plug hand taps have a chamfer length of 3 to 5

threads and are designed for use after the taper tap.

Bottoming hand taps are used for threading the

bottom of a blind hole. They have a very short cham-

fer length of only 1 to 1 1/2 threads for this purpose.

This tap is always used after the plug tap has already

Figure 2-9.—Types of common taps.

2-7