Socket Handles

There are four types of handles used with these

sockets. (See fig. 2-5) Each type has special advan-

tages, and the experienced worker chooses the one

suited for the job at hand. The square driving lug on

the socket wrench handles has a spring-loaded ball

that fits into a recess in the socket receptacle. This

mated ball-recess feature keeps the socket engaged

with the drive lug during normal usage. A slight pull

on the socket, however, disassembles the connection.

RATCHET.— The ratchet handle has a reversing

lever that operates a pawl (or dog) inside the head of

the tool. Pulling the handle in one direction causes the

pawl to engage in the ratchet teeth and turn the socket.

Moving the handle in the opposite direction causes

the pawl to slide over the teeth, permitting the handle

to back up without moving the socket. This allows

rapid turning of the nut or bolt after each partial turn

of the handle. With the reversing lever in one position,

the handle is used for tightening. In the other position,

it is used for loosening.

HINGED HANDLE.— The hinged handle is also

very convenient. To loosen tight nuts, swing the han-

dle at right angles to the socket. This gives the greatest

possible leverage. After loosening the nut to the point

where it turns easily, move the handle into the vertical

position, and then turn the handle with the fingers.

SLIDING T-BAR HANDLE.— When using the

sliding bar or T-handle, the head can be positioned

anywhere along the sliding bar. Select the position

that is needed for the job at hand.

SPEED HANDLE.— The speed handle is

worked like the wood-worker’s brace. After the nuts

are first loosened with the sliding bar handle or the

ratchet handle, the speed handle can be used to re-

move the nuts more quickly. In many instances the

speed handle is not strong enough to be used for

breaking loose or tightening the nut. The speed socket

wrench should be used carefully to avoid damaging

the nut threads.

Accessories

To complete the socket wrench set, there are sev-

eral accessory items. Extension bars of different

lengths are made to extend the distance from the

socket to the handle. A universal joint allows the nut

to be turned with the wrench handle at an angle.

Universal sockets are also available. The use of uni-

versal joints, bar extensions, and universal sockets in

combination with appropriate handles makes it possi-

ble to form a variety of tools that will reach otherwise

inaccessible nuts and bolts.

Another accessory item is an adapter that allows

you to use a handle having one size of drive and a

socket having a different size drive. For example, a

3/8- by 1/4-inch adapter makes it possible to turn all

1/4-inch square drive sockets with any 3/8-inch

square drive handle.

HACKSAW

The hacksaw is a handy portable metal cutting

tool that can be used for cutting sheet metal, bolts, and

pipe. A hacksaw cuts on the push stroke only; the

blade should be installed in the frame with the teeth

facing away from the handle. Figure 2-1, view H,

shows two types of hacksaws with the blade in the

proper position.

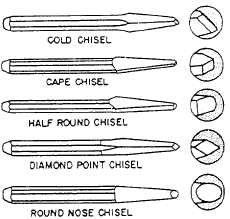

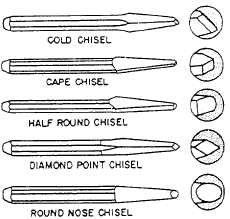

CHISELS

Chisels are tools that can be used for chipping or

cutting metal. They will cut any metal that is softer

than the materials of which they are made. Chisels are

made from a good grade tool steel and have a hard-

ened cutting edge and beveled head. Cold chisels are

classified according to the shape of their points, and

the width of the cutting edge denotes their size. The

most common shapes of chisels are flat (cold chisel),

cape, round nose, and diamond point (fig. 2-7).

Figure 2-7.—Types of points on metal cutting chisels.

2-5