(fig. 2-3) is required. This wrench has a curved arm

with a lug or hook on the end. This lug fits into one of

the notches of the nut and the handle is turned to

loosen or tighten the nut. This spanner may be made

for just one particular size of notched nut, or it may

have a hinged arm to adjust it to a range of sizes.

Another type of spanner is the pin spanner. Pin

spanners have a pin in place of a hook. This pin fits

into a hole in the outer part of the nut.

Face pin spanners are designed so the pins fit into

holes in the face of the nut (fig. 2-3).

When you use a spanner wrench, you must ensure

the pins, lugs, or hooks make firm contact with the nut

while the turning force is applied. If this is not done,

damage will result to either personnel, tools, or equip-

ment.

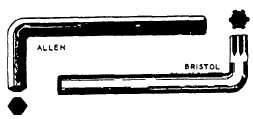

SETSCREW WRENCHES

(ALLEN AND BRISTOL)

In some places it is desirable to use recessed heads

on setscrews and capscrews. The Allen screw is used

extensively on office machines and in machine shops.

The Bristol is used infrequently.

Figure 2-3.—General purpose spanner wrenches.

Recessed head screws usually have a hexshaped

(six-sided) recess. To remove or tighten this type of

screw requires a special wrench that will fit in the

recess. This wrench is called an Allen wrench. Allen

wrenches are made from hexagonal L-shaped bars of

tool steel (fig. 2-4). They range in size up to 3/4 inch.

When using the Allen wrench, make sure you use the

correct size to prevent rounding or spreading the head

of the screw. A snug fit within the recessed head of the

screw is an indication that you have the correct size.

The Bristol wrench is made from round stock. It

is also L-shaped, but one end is fluted to fit the flutes

or little splines in the Bristol setscrew (fig. 2-4).

Figure 2-4.—Allen and Bristol wrenches.

2-3