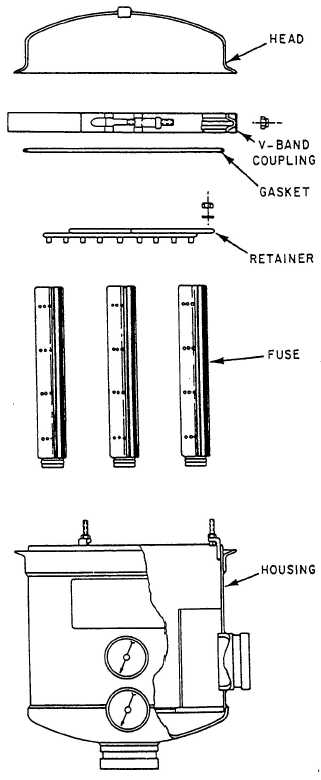

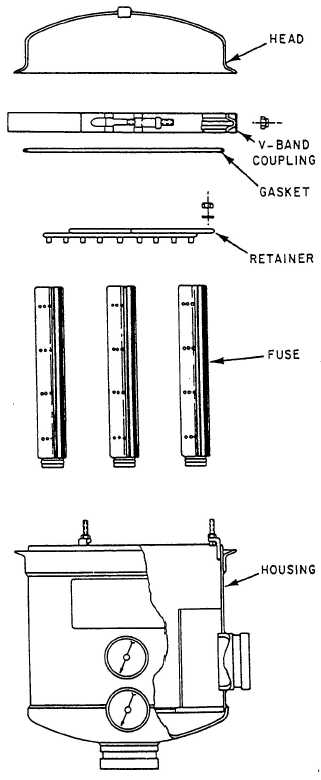

FUEL-QUALITY MONITORS

Fuel-quality monitors (formerly called go/no-go

gages) are installed after filter/separators on truck fill

stands and on all equipment that directly fuel

aircraft. Monitors are not required for use with

product receipt filters or those used exclusively for

recirculation of fuel. A pressure gage is also installed

on each monitor housing so that the differential

pressure across the elements can be recorded. If the

filter/separator also incorporates fuel monitor

elements, the gage or gages are installed so that the

pressure losses across the filter elements and monitor

elements can be recorded separately.

The fuel-quality monitor (fig. 7-2) provides a

continuous check on the cleanness of the fuel passing

through the filter/separator. Fuel that meets a

predetermined standard of cleanness passes through

the monitor with a minimum drop in pressure. Fuel

containing quantities of solids and/or water above the

predetermined acceptable level is automatically cut

off.

The fuel-quality monitor has an aluminum

housing and various numbers of fuses, depending on

the model. Each fuse of the monitor is a self-

contained unit consisting of specially treated paper

washers housed within a metallic housing and fitted

with plastic end fittings. The sensing washers,

housed within the metallic housing, absorb free or

suspended water from the fuel.

RELAXATION CHAMBERS

A relaxation chamber, consisting of a tank or

piping, follows the fuel monitor, or filter/separator if

no monitor is installed in the system. This chamber

allows static electric charges, which develop as the

fuel passes through the filtration equipment, to

“relax” before the fuel enters a tank. Since the fuel

must be in contact with the metal walls of the

relaxation device for at least 30 seconds, the exact

size of the relaxation tank, or length of piping, is

determined from the maximum flow rate of the

system. Only one relaxation chamber is needed for

each fuel monitor, filter/separator combination. Any

tank, chamber, or other arrangement used to meet

this requirement must assure complete product

turnover, have a water drain at its low point, and a

manual or automatic air eliminator.

Figure 7-2.—Fuel-quality monitor.

7-3