Pantograph

and/or

hose

with

approved,

nonlubricated swivel. Zerk-type grease fittings in

pantograph swing joints are not authorized,

because of the possibility of contaminating the

fuel with grease.

Dry-break quick-disconnect fuel-service coupling

with a 60- to 100-mesh strainer.

Single-point-pressure refueling nozzle with a 55-

psi maximum pressure regulator.

Fire extinguisher(s) in accordance with NAVAIR

00-80R-14 (minimum of one 150-pound Halon or

TAU unit per fueling point).

Emergency eyewash/shower system available in

the immediate area.

Fire alarm.

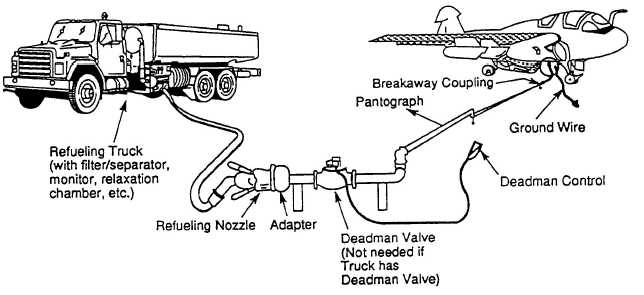

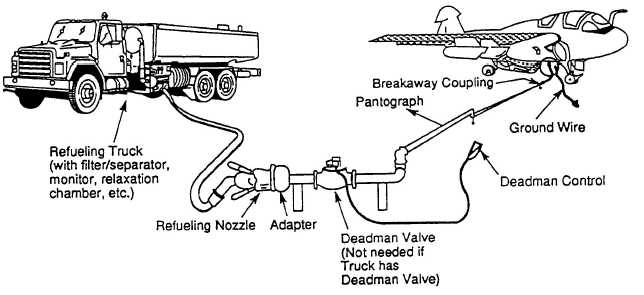

MOBILE AIRCRAFT REFUELERS

Mobile refuelers are used primarily for cold

fueling operations, with occasional hot-refueling

operations at stations where installation of a direct

refueling system is not justified. If continuous or

extensive hot fueling is being performed with mobile

refuelers, the use of an anchored pantograph, as

shown in figure 7-5, should be considered.

Mobile aircraft refuelers vary in capacity and

configuration. However, whether contractor- or

Government- owned, all mobile aircraft refuelers

have

the

same

basic

requirements.

These

requirements are the following:

Tank construction is one compartment only, with

necessary baffles. Tank must completely drain at

the low point without traps of liquid remaining

in pockets. The tank is designed so that all

portions are accessible for cleaning and

maintenance.

Tank is aluminum or stainless steel.

Tank top opening(s) must be semi-permanently

secured and used only for inventory and for

interior inspections and repairs. Manhole covers

must in-corporate a fusible plug or plugs, each

equipped with fine screens to provide additional

emergency release of vapor.

Tank must be configured for bottom loading. The

bottom loading hardware includes a cutoff valve,

an adapter to accept the standard pressure (SPR)

nozzle, and must be of sufficient size to receive

the product at 600 gallons per minute. A fill

stand anti-driveaway device is incorporated.

Each tank must have an electronic system for

controlling the filling operation (Scully Dynaprobe

or equivalent) that is compatible with the system on

the truck fill stand. It should be located near the

bottom loading adapter and include art anti-

driveaway feature (can be combined with anti-

driveaway device previously mentioned).

The piping system, including all hardware

components, must be capable of dispensing fuel

at the rated flow. A flow diagram of the general

configuration of these system devices is shown in

figure 7-6.

Figure 7-5.—Hot-refueling with truck and pantograph.

7-8