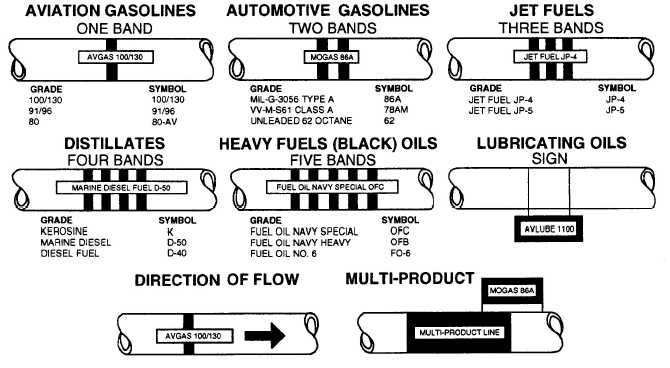

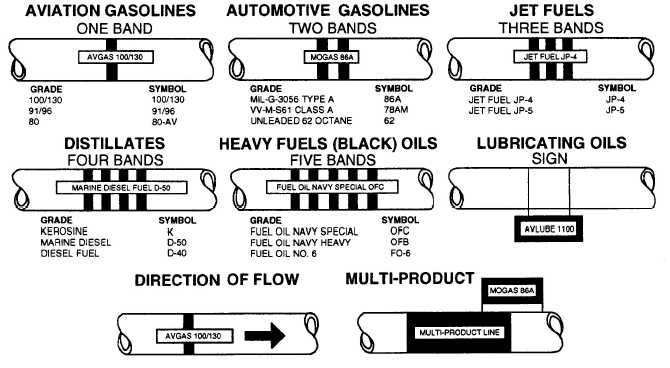

(fig. 7-3) are placed next to all operating accessories

such as valves, pumps, regulators, and manifolds.

Table 7-1 lists the sizes of bands and letters used for

petroleum products.

AIRCRAFT FUELING SYSTEMS

LEARNING OBJECTIVES: Identify the

typical fueling systems used on shore

activities. Describe the equipment contained

in each system.

The following are three typical aircraft fueling

systems used on shore activities:

• Aircraft Direct-Refueling System (more

commonly known as a “pit”).

• Mobile Aircraft Refuelers. These are tanker

trucks of various capacities and configurations.

• Portable Fueling Systems. These are air-

transportable, advanced base systems used primarily

to support tactical operations. As an ABF, you most

likely will never use this type system; therefore, it is

not discussed further in this manual.

AIRCRAFT DIRECT-REFUELING

SYSTEM (PIT)

Aircraft direct-refueling systems (fig. 7-4) are

designed primarily for “hot” refueling of aircraft. All

direct-refueling systems have the following minimum

features:

Filter/separator.

Fuel-quality monitor.

Relaxation chamber or equivalent piping configuration

capable of providing 30 seconds of static relaxation

from point of last filtration to the nozzle.

Diaphragm-operated primary control valve.

Remote, hand-held, deadman control for each pan-

tograph or hose installed at each station.

Emergency pump-shutoff switch.

Meter on each station outlet.

Recirculation/flushing capability of the nozzle and/or

hose/pantograph system.

Emergency dry-breakaway coupling on each hose or

pantograph.

Bonding/grounding cable. This requirement is

considered satisfied if the fueling hose/pantograph sys-

tem has continuity (10,000 ohms or less).

Figure 7-3.—Identification for bulk petroleum product lines.

7-6