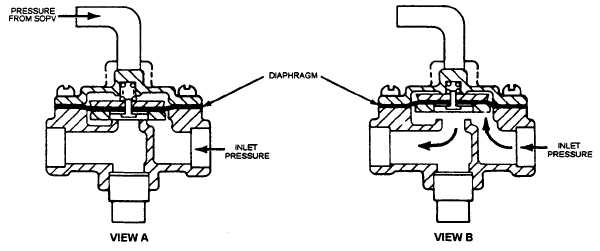

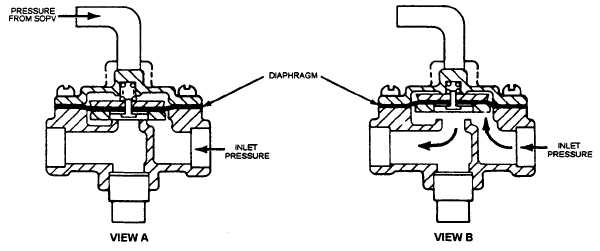

Hytrol Valve

The hytrol valve (fig. 5-5) either isolates inlet

pressure from the pressure-reducing control valve, or

vents inlet pressure to the pressure-reducing control

valve and the fuel port of the main valve. Pressure

directed from the SOPV to the top of the diaphragm

holds the hytrol valve closed. When this pressure is

vented (also through the SOPV), the inlet pressure

opens the hytrol valve allowing fuel flow. No adjust-

ments are made to the hytrol valve. It is either open

or closed.

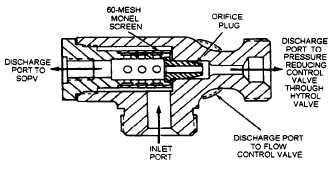

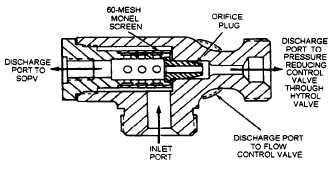

Ejector-Strainer

The ejector-strainer (fig. 5-6) reduces inlet pres-

sure to the pressure-reducing control valve, and

filters fuel. It consists of an orifice plug and a 60-

mesh monel screen located between the inlet port and

three discharge ports. The orifice plug creates

reduced pressure by increasing fuel velocity (like an

eductor). This aids in vacating the cover chamber of

the fuel valve. The monel screen traps foreign

particles and contaminating substances. The three

discharge ports direct filtered fuel to the pressure-

reducing control valve, the flow control valve, and the

SOPV.

Solenoid-Operated Pilot Valve (SOPV)

The SOPV (fig. 5-7) shifts the Cla-Val assembly

from the defuel to the fuel mode of operation, and vice

versa. The SOPV is a direct acting, solenoid-actuated

valve. It is a four-way valve with a grooved stem that

moves back and forth in a machined bore inside the

body. When the solenoid is energized in the fueling

mode, the stem is drawn against spring compression

by the magnetic pull of the solenoid. When the

solenoid is deenergized in the defueling mode, the

Figure 5-6.—Ejector strainer.

the stem is returned by the extension of the core

spring. Movement of the valve piston directs full flow

in one direction or full flow in the opposite direction.

There is no closed-port position. The valve is also

equipped with a manual operator. Manual operation

is done by pushing upward on the button at the lower

end of the control. A quarter-turn clockwise locks the

manual operator in place.

The solenoid is housed in an explosion-proof case

and meets the requirements for use in hazardous

locations.

Flow Control Valve (Needle Valve)

The flow control valve (fig. 5-8) consists of a

needle valve with a spring and disk assembly within

a housing. The housing cover can he removed to allow

for needle valve adjustment. The flow control valve is

installed in the line between the ejector-strainer and

the fuel valve cover chamber.

The flow control valve, by virtue of its construction,

controls the flow from the fuel valve cover chamber,

Figure 5-5.—Hytrol valve.

5-4