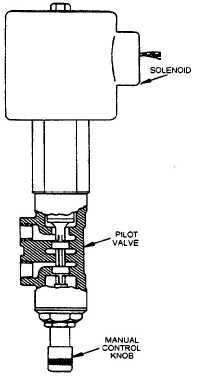

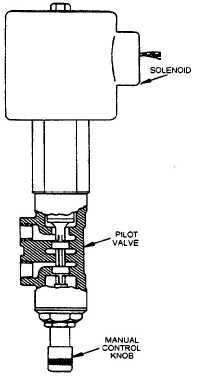

Figure 5-7.-Solenoid-operated pilot valve (SOPV).

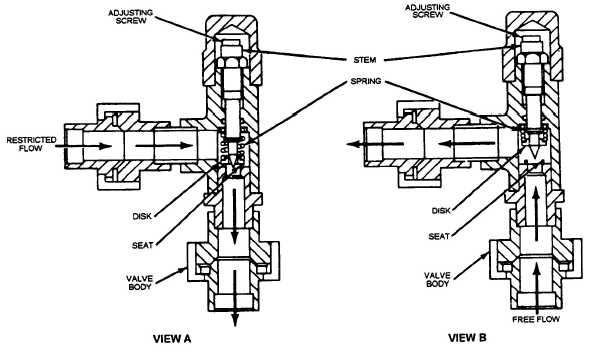

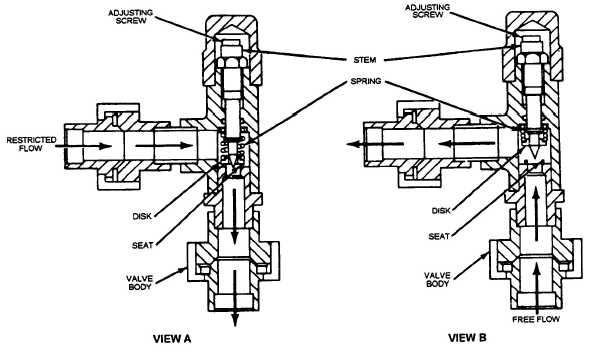

which controls the reaction time of the fuel valve. This

is done by restricting fuel flow through the needle

valve and disk assembly. Flow in the opposite direction

lifts the disk up off the seat, permitting free flow.

Operation of the Cla-Val

A step-by-step analysis of the valve’s operation is

as follows. Figure 5-9 shows the valve in the fueling

position.

1. The solenoid is energized.

2. The SOPV directs pressure from the main valve

inlet into the cover chamber of the defueling valve,

holding it closed.

3. The SOPV also vents the cover chamber of the

hytrol valve to the defueling line. This permits the

pressure-reducing control valve to take over control of

the fueling valve.

4. When the pressure-reducing control valve goes

into operation, high pressure fuel enters the fueling

valve and bypasses through the ejector-strainer to the

pressure-reducing control valve, which is held open by

its compression spring. With pressure at the pressure-

reducing control valve below the adjusted setting, a

maximum flow is permitted through the ejector-

strainer. This creates a reduced pressure in the main

valve cover chamber, which allows the fueling valve to

open to build up pressure in the downstream system.

The increasing downstream pressure is transmitted

through the pressure reducing control valve line to the

under side of the pressure reducing control valve dia-

phragm.

Figure 5-8.—Flow control valve (needle valve).

5-5