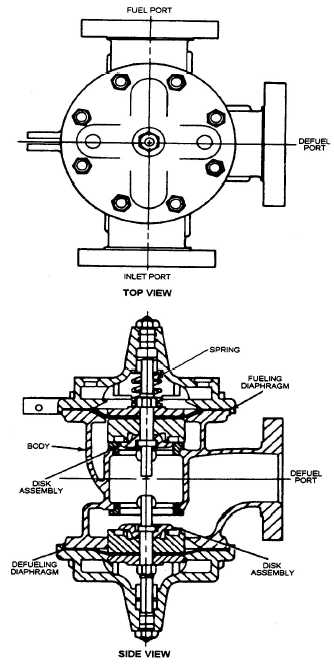

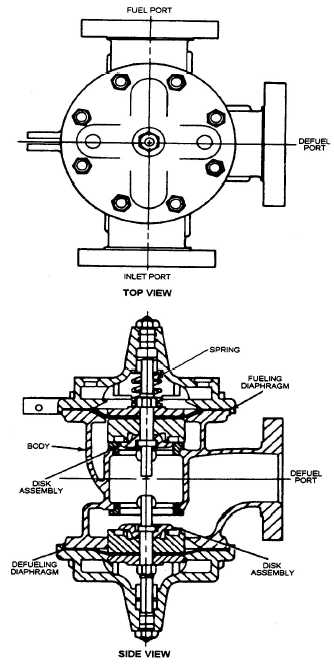

Main Fuel/Defuel Valve

The main valve (fig. 5-2) is actually two single-

seated globe valves built into a common body. Each of

the valves performs a separate and distinct function,

one is the fueling valve and the other is the defueling

valve.

Each valve employs a well-supported and

reinforced diaphragm as its operating means. The

Figure 5-2.—Main valve.

fueling valve is spring-loaded to close; therefore, it is

normally closed. The defuel valve is inverted (upside

down) and held open by its own weight.

The main valve directs fuel flow from the inlet

port to the fuel port when fueling, and fuel flow from

the fuel port to the defuel port when defueling. The

fuel and defuel valves are controlled by pressure

acting on a diaphragm. The change from the fuel to

defuel mode is accomplished by energizing or

deenergizing the solenoid-operated pilot valve

(SOPV), or by excessive delivery pressure.

When pressure above the fueling valve

diaphragm is vented off, inlet pressure on the

diaphragm lifts its disk assembly, opening the fuel

valve. Simultaneously, pressure is applied to the

bottom of the defueling valve diaphragm, seating its

disk assembly and closing the defuel valve.

When pressure underneath the defueling valve

diaphragm is vented off, its disk assembly falls, and

the defuel valve opens. Simultaneously, pressure is

applied to the top of the fuel valve diaphragm (both

line and spring). When this pressure overcomes the

inlet pressure, its disk assembly seats, closing the

fuel valve.

The main valve is controlled by a set of smaller

valves using line pressure, thus providing fully

automatic operations. The SOPV shifts the Cla-Val

assembly from defueling to fueling, and from fueling

to defueling. The flow control valve regulates the

opening speed of the fueling side of the main valve.

The hytrol valve either isolates inlet pressure from

the pressure-reducing control valve, or vents inlet

pressure to the pressure-reducing control valve and

the fuel port of the main valve. The pressure-

reducing control valve regulates delivery pressure.

The ejector-strainer aids in relieving pressure above

the diaphragm of the fueling valve and prevents

foreign particles from entering the pressure-reducing

control valve. The pressure relief control valves open

to shift to the defueling mode if the delivery pressure

exceeds the preset limit.

Pressure Relief Control

Valves

The pressure relief control valves (fig. 5-3) open

to shift the main valve to the defueling mode when

delivery pressure exceeds the preset adjustment.

There are two pressure-relief control valves for each

Cla-Val fueling unit. One valve acts as a pressure

5-2