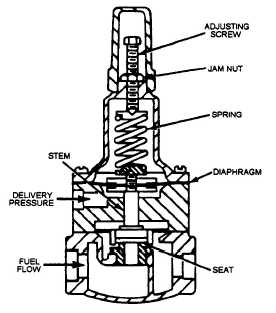

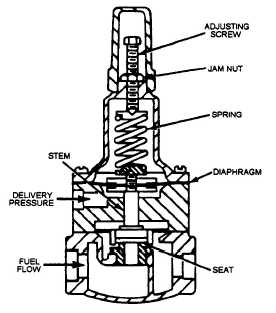

Figure 5-3.—Pressure-relief control valve.

relief for the fuel valve, and the other for the defuel

valve.

Each pressure-relief control valve contains a

stem, a diaphragm, a spring, and an adjusting screw.

Each valve is a direct acting, spring-loaded valve,

designed with a large diaphragm working area in

relation to the valve area seat, to ensure positive

operation. It is held closed by the force of the

compression spring. Pressure adjustment is made by

rotating the adjusting screw to vary spring

compression on the diaphragm. Compressing this

spring increases the pressure at which the valve

opens. The spring can be adjusted to provide a relief

setting from 20 to 70 psi. The adjusting screw is

covered by a protective housing.

When the controlling pressure under the dia-

phragm exceeds the set spring force, the disk is lifted

off the seat, permitting flow.

The pressure relief for the defuel valve is set

about 7 1/2 psi above delivery pressure. The pressure

relief for the fuel valve is set approximately 2 1/2 psi

above delivery pressure. The opening of the pressure

relief control valve for the fueling valve increases the

closing speed of the fueling valve. The opening of the

pressure relief control valve for the defueling valve

vents pressure from the bottom of the defuel valve

diaphragm, opening it.

Pressure-Reducing Control

Valve

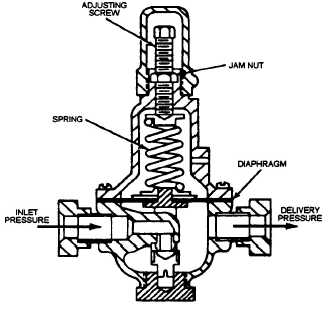

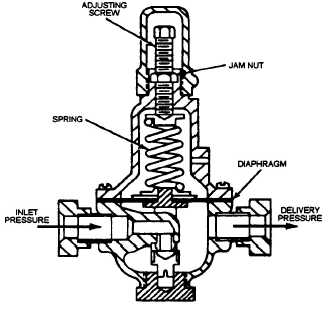

The pressure-reducing control valve (fig. 5-4)

steadily reduces a higher initial pressure to a lower

pressure and regulates the delivery pressure when

the main valve is in the fueling mode.

The pressure-reducing control valve is a direct

acting, spring-loaded valve designed with a large dia-

phragm working area in relation to the valve seat to

ensure sensitive control and accurate regulation of

the delivery pressure. Pressure adjustment is made

by rotating the adjusting screw to vary spring

compression on the diaphragm. Compressing this

spring in-creases the delivery pressure setting. The

spring can be adjusted to provide delivery from 15 to

100 psi. The adjusting screw is also covered by a

protective housing.

The pressure-reducing control valve normally is

held open by the force of the compression spring.

When the delivery pressure acting upon the lower

side of the diaphragm exceeds the force of the

compression spring, the valve closes.

Conversely, when the delivery pressure reduces

below the spring setting, the valve opens. Thus, a

constant delivery pressure is maintained by

balancing delivery pressure against spring pressure.

The valve can be easily regulated by turning the

adjusting screw, which provides a simple means of

pressure adjustment.

Figure 5-4.—Pressure-reducing control valve.

5-3