handles. See figure 2-8. These pliers are very

powerful gripping tools. The inner surfaces of the

jaws consist of a series of coarse teeth formed by

deep grooves. This construction makes a surface

usable for grasping cylindrical objects. Channel-

lock pliers have grooves on one jaw and lands on

the other. The adjustment is effected by changing

the position of the grooves and lands. Channel-

lock pliers are less likely to slip from the adjust-

ment setting when gripping an object. Use the

channel-lock pliers where it is impossible to use

a more adapted wrench or holding device. Many

nuts and bolts and surrounding parts have been

damaged by improper use of channel-lock pliers.

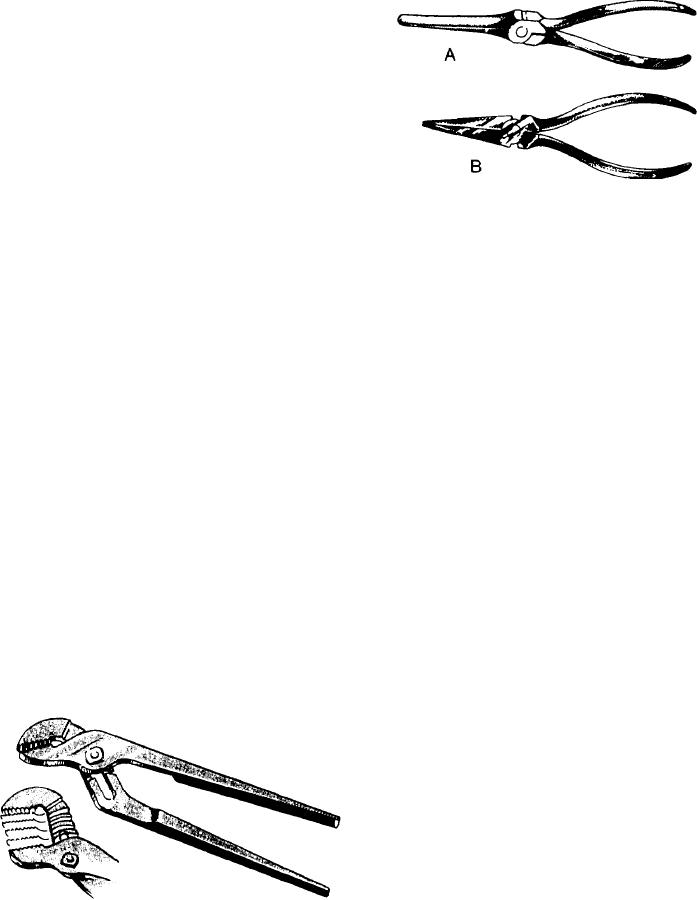

Figure 2-9.-Pliers (A) duckblll; (B) needle-nose.

DUCKBILL PLIERS.-- Duckbill pliers have

long wide jaws and slender handles. Duckbills are

DIAGONAL PLIERS.-- Diagonal cutting

pliers are an important tool for you to use. They

used in confined areas where the fingers cannot

be used. The jaw faces of the pliers are scored to

are used for cutting small wire and cotter pins,

aid in holding an item securely. See figure 2-9,

and so forth. Since they are small, they should

view A.

not be used to cut large wire or heavy material.

The pliers will be damaged by such use and will

not be effective to cut what they were designed

NEEDLE-NOSE PLIERS.-- Needle-nose

pliers are used in the same manner as duckbill

to cut. They can also be used to remove small

pliers. See figure 2-9, view B, There is a difference

cotter pins where a new pin is to be used when

in the design of the jaws, Needle-nose jaws are

the work is finished. This is done by gripping the

tapered to a point, which makes them adapted to

pin near the hinge of the pliers and lifting up on

the handles, releasing the pin, getting a new grip,

installing and removing small cotter pins. The

pliers have serrations at the nose end and a side

and repeating until the pin is removed.

The inner jaw surface is a diagonal straight

cutter near the throat. Use needle-nose pliers to

hold small items steady, to cut and bend wire, or

cutting edge offset approximately 15 degrees. This

to do numerous other jobs that are too intricate

design permits cutting objects flush with the

surface. The diagonal cutting pliers are not

or too difficult to be done by hand alone.

designed to hold objects. To use enough force to

NOTE: Duckbill and needle-nose pliers

hold an object, the pliers will cut or deform the

are especially delicate. Care should be

object. The sizes of the diagonal pliers are

exercised when using these pliers, to

indicated by the overall length of the pliers.

prevent springing, breaking, or chipping

the jaws. Once these pliers are damaged,

SAFETY-WIRE PLIERS.-- When installing

they are practically useless.

equipment, you may need to lockwire (usually

referred to as safety wire) designated parts of the

installation. The process of lockwiring can be

accomplished faster and neater with the use of

special pliers. See figure 2-10.

Safety-wire pliers are three-way pliers--they

hold, twist, and cut. They are designed to make

a uniform twist and to reduce the time required

in twisting the safety wire.

To operate, grasp the wire between the two

diagonal jaws of the pliers. As the handles are

squeezed together, the thumb and forefinger

brings the outer (locking) sleeve into the locked

position. A pull on the knob of the pliers can

make a uniform twist. The spiral rod may be

pushed back into the pliers without unlocking

Figure 2-8.-Channel-lock pliers.

2-8