made in deep lengths to fit over spark plugs and

extensions, universals, adapters, and a variety of

long bolt ends.

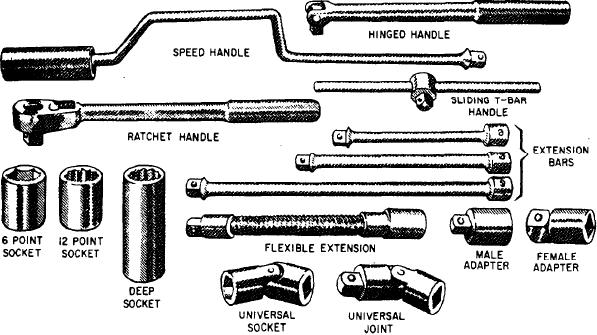

sockets. See figure 2-2.

There are four types of handles used with these

sockets. See figure 2-2. Each type has special

SOCKETS.-- A socket has an opening cut in

advantages, and the good mechanic chooses the

one end to fit a drive on a detachable handle. The

one best suited to the job at hand. The square

handle drive is usually square. On the other end

driving lug on the socket wrench handles has a

of the socket is a 6-point or 12-point opening very

spring-loaded ball that fits into a recess in the

much like the opening in the box-end wrench. The

socket receptacle. The tool design holds the

12-point socket needs to be swung only half as

assembly together. This mated ball-recess feature

far as the 6-point socket before it may be lifted

prevents the parts of the wrench from falling apart

and fitted on the nut for a new grip. It can be used

during normal usage, but a slight pull disassembles

in closer quarters where there is less room to move

any wrench connection.

the handle. Most sockets have 12 points. Use the

6-point socket with nuts made of stainless steel.

RATCHET HANDLE.-- The ratchet handle

Stainless steel is a harder metal than that of the

has a reversing lever that operates a pawl (or dog)

wrench. Extensive use of a 12-point socket on such

inside the head of the tool. Pulling the handle in

nuts or bolts would cause excessive wear on the

one direction causes the pawl to engage in the

12 points. The socket might fail to hold. By con-

ratchet teeth and to turn the socket. Moving in

trast, because of the greater holding surface, a

the opposite direction causes the pawl to slide over

6-point socket holds the stainless steel nut better.

the teeth, permitting the handle to back up

The 6-point socket offers less chance for wear of

without moving the socket. This feature allows

the wrench.

rapid turning of the nut or bolt after each partial

Sockets are classified for size according to two

turn of the handle. With the reversing lever in one

position, the handle can be used for tightening.

factors. One is the drive size or square opening,

which fits on the square drive of the handle. The

In the other position, it can be used for loosening.

other is the size of the opening in the opposite end,

which fits the nut or bolt. The standard toolbox

HINGED HANDLE.-- The hinged handle is

has sockets that have 1/4- and 3/8-inch-square

also very convenient. To loosen a tight nut, swing

the handle at right angles to the socket. This gives

drivers. The openings that fit the bolt or nut are

the greatest possible leverage. After loosening the

graduated in 1/16-inch sizes. Sockets are also

Figure 2-2.-Typical socket wrench set.

2-4