AFTERBURNER SECTION

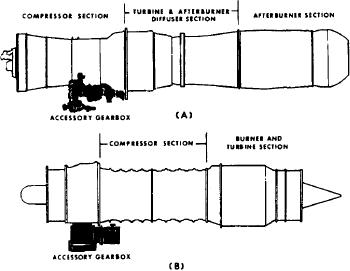

The parts of an axial-flow engine accessory

section are the accessory gearbox and a power

The afterburner increases or boosts the normal

takeoff assembly. These units contain the

thrust rating of a gas turbine engine. There are

necessary drive shafts and reduction gears. Views

times when the maximum normal thrust of an

A and B of figure 1-47 show the location of the

engine is not enough. For instance, it is

accessory gearbox.

conceivable that although the in-flight require-

The accessory gearbox and the power takeoff

ments are met satisfactorily by an engine of

are located near each other. There are two

moderate size, the aircraft still may not have

factors that affect the location of gearboxes in

good takeoff performance. With afterburning,

general. These factors are engine diameter and

maximum thrust is obtained without sacrificing

engine installation.

the economy of the small basic gas turbine.

Designers strive to reduce engine diameter to

Increased thrust is required for takeoff, emergen-

make the engine more streamlined, thereby

cies, and combat conditions.

increasing performance by reducing drag. Also,

engine installation in a particular aircraft may

The afterburner duct replaces the usual air-

dictate the location or rearrangement of the

craft tailpipe. Actually, it is more like a converted

accessory gearboxes.

tailpipe. It functions as the engine tailpipe during

The accessories on engines are the fuel control

nonafterburning (cold) operation and is also the

with its governing device, the high-pressure fuel

main working element of the afterburner. The

pump(s), and a breather screen or other means

entire afterburner is projected from the engine.

for venting the oil system. Other parts are oil

It is supported only at the exhaust end where it

sump, oil pressure and scavenge pumps, auxiliary

is bolted to the engine.

fuel pump, starting fuel pump, and other

accessories, including starter, generator, and

The essential working element of the after-

tachometer. Although these accessories are

burner is an afterburner duct. A flameholder or

essential, the particular combination of engine-

diffuser and a variable-area exhaust nozzle are the

driven accessories depends upon the use for which

other parts (fig. 1-45).

the engine is designed.

The accessories mentioned above (except

The afterburner duct is the main working

starters) are of the engine-driven type. There are

element of the afterburner. It's designed so

the nondriven-type accessories such as booster

that the normal pressure relationship between

coils or ignition exciters, fuel and oil filters,

the air entering the main engine turbine and

barometric units, drip valves, compressor bleed

the air leaving the turbine is not upset. Since

valves, and relief valves.

the duct acts as a burner, the inlet air velocity

must be sufficiently low to support stable

combustion and to avoid excessive pressure

losses. For these purposes a diffuser is located

between the turbine outlet and the tailpipe

burner inlet. Thus, the burner section of the

duct can reduce gas velocities so they do

not exceed the flame propagation rate. Other-

wise, the flame could not get a foothold,

because the onrushing turbine exhaust would

simply push the burning mixture right out

the exhaust nozzle. In addition to the diffuser,

some mechanical mixing of the fuel and air

is necessary. Mixing by diffusion is too slow

a process to be an aid in forming a combustible

mixture.

The flameholders provide local turbulence and

reduce velocity, which aids combustion stability.

The flameholders are located downstream from

Figure 1-47.-Accessory gearbox. (A) Mounted beneath the

the fuel-injection nozzles, thereby allowing time

compressor; (B) mounted beneath the front bearing support.

1-32