The elements of the exhaust cone assembly

are required for inner cone support, these struts

also form fairings around the rods.

consist of an outer shell or duct, an inner cone,

The centrally located inner cone fits rather

and three or four radial hollow struts or fins. Tie

closely against the rear face of the turbine disc.

rods aid the struts in supporting the inner cone

This fit prevents turbulence of the gases as they

from the outer duct.

leave the turbine wheel. The cone is supported by

The outer shell or duct, made of stainless steel,

is attached to the rear flange of the turbine case.

the radial struts, which are usually vertical and

horizontal in relation to the normal position of

This element collects and delivers the exhaust

the engine. In some configurations, there is a small

gases. The gases flow either directly or through

hole located in the exit tip of the cone (fig. 1-40).

a tailpipe to the jet nozzle, depending on whether

This hole allows cooling air to circulate from the

or not a tailpipe is required. There is no need for

exit end of the cone. The pressure of the gases

a tailpipe in some engines. For instance, the

is relatively high in the interior of the cone and

required engine-installation space in wing roots,

against the face of the turbine wheel. The flow

pods, or wings is short and requires very little

of air is positive, since the air pressure at the

tailpipe. In which case the exhaust duct and ex-

turbine wheel is relatively low due to rotation of

haust nozzle will suffice. The construction of the

the wheel, thus air circulation is assured. The gases

duct includes such features as a predetermined

for cooling the turbine wheel return to the path

number of thermocouple bosses for installing

of flow by passing through the clearance between

exhaust gas temperature thermocouples. Also,

the disc and the cone. The clearance between the

there must be insertion holes for the supporting

tie rods. In some cases, there are no requirements

turbine disc and the inner cone must be checked

periodically since the higher pressures aft tend to

for tie rods for supporting the inner cone from

push the inner cone against the turbine wheel.

the outer duct. If such is the case, the hollow struts

The exhaust cone assembly is the terminating

provide the sole support of the inner cone; the

part of the basic engine. The remaining parts (the

struts being spot-welded in position to the inside

surface of the duct and to the inner cone,

tailpipe and jet nozzle) are usually considered air-

frame parts.

respectively.

The tailpipe pipes the exhaust gases out of the

The radial struts actually have a twofold

airframe. Actually, the tailpipe imposes a penalty

function. They not only support the inner cone

on the operating efficiency of the engine in the

in the exhaust duct, they also perform the

form of heat and duct (friction) losses. These

important function of straightening the swirling

losses materially affect the final velocity of the

exhaust gases, which otherwise would leave the

exhaust gases and, hence, the thrust.

turbine at an angle of about 45 degrees. If tie rods

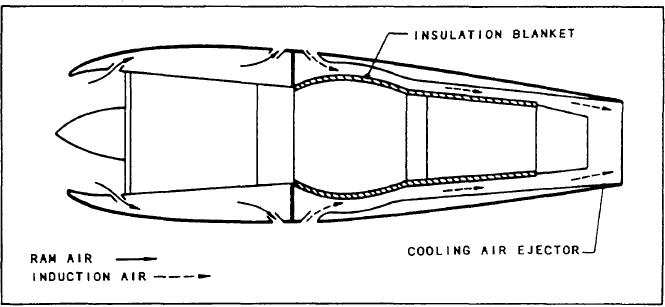

Figure 1-41.-Exhaust system insulation blanket.

1-28