nozzle cluster. These nozzles are the dual-orifice

mechanical energy to drive the compressor and

necessary accessories. This is the sole purpose of

(duplex) type that require the use of a flow-divider

(pressurizing valve), as mentioned above in the

the turbine. This function absorbs about 60 to 80

percent of the total pressure energy from the

can-type combustion chamber. Preswirl vanes are

located around each of the nozzles for imparting

exhaust gases. The exact amount of energy

a swirling motion to the fuel spray. This results

absorption at the turbine is determined by the load

in better atomization of the fuel, thus better

the turbine is driving. The compressor size, type,

burning and efficiency.

if the engine is a turbo-propeller type also effect

The swirl vanes perform two important

functions imperative to proper flame propagation:

absorption.

The turbine section of a turbojet engine is

1. High flame speed: Better mixing of air and

located aft, or downstream, of the combustion

fuel, ensuring spontaneous burning.

chamber section. Specifically, it is directly behind

2. Swirling prevents the flame from moving

the combustion chamber outlet.

rapidly rearward.

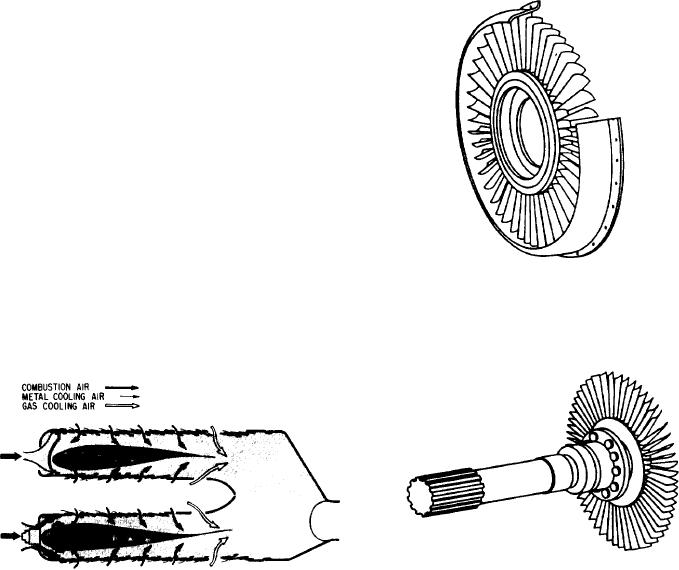

The turbine assembly consists of two basic

The swirl vanes greatly aid flame propagation,

elements, the stator and the rotor, as does the

since a high degree of turbulence in the early

compressor unit. These two elements are shown

combustion and cooling stages is desirable. The

in figures 1-30 and 1-31.

vigorous mechanical mixing of the fuel vapor with

The stator element is known by a variety of

the primary air is necessary, since mixing by

names. Turbine nozzle vanes, turbine guide vanes,

diffusion alone is too slow. This same mechanical

mixing is also established by other means, such

as placing coarse screens in the diffuser outlet,

as is the case in most axial-flow engines.

The can-annular combustion chambers also

must have the required fuel drain valves, located

in two or more of the bottom chambers, thereby

assuring proper drainage and eliminating the

possibility of residual fuel burning during the next

start cycle.

The flow of air through the holes and louvers

of the can-annular chambers is the same as the

flow through other types of burners. Figure 1-29

shows the flow of combustion air, metal-cooling

air, and the diluent or gas-cooling air. Pay

particular attention to the direction of airflow,

indicated by the arrows.

TURBINE SECTION

The turbine transforms a portion of the kinetic

Figure 1-30.-Stator element of the turbine assembly.

(velocity) energy of the exhaust gases into

Figure 1-31.-Rotor element of the turbine assembly.

Figure 1-29.-Airflow through a can-annular chamber.

1-23