the axis in this instance being the rotor shaft

their J57 axial-flow turbojet engine. Since this

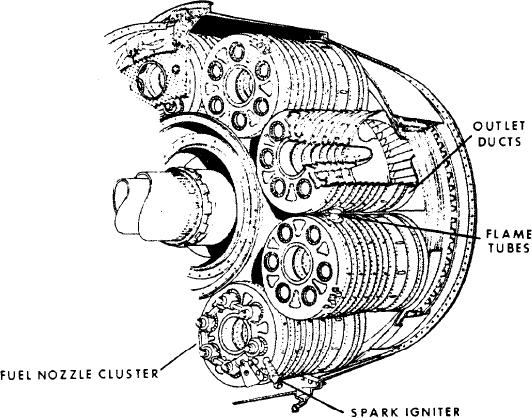

housing. Figure 1-28 shows this arrangement to

engine features the split-spool compressor, it

advantage.

requires combustion chambers capable of meeting

The combustion chambers are enclosed by a

the stringent requirements of maximum strength,

removable steel shroud, which covers the entire

limited length, and high overall efficiency. These

burner section. This feature makes the burners

attributes are necessary because of the high air

readily available for any required maintenance.

pressures and velocities present in a split-spool

The burners are interconnected by projecting

compressor, a l o n g with the shaft length

flame tubes, which help the engine-starting

limitations.

process in the can-type combustion chamber.

The split-spool compressor requires two

These flame tubes perform a function identical

concentric shafts joining the turbine stages to their

with those previously discussed, the only

respective compressors. The front compressor,

difference being in construction details.

joined to the rear turbine stages, requires the

Figure 1-28 also reveals that each of the

longest shaft. This shaft is inside the other. A

combustion chambers contains a central bullet-

limitation of diameter is imposed, so that the

shaped perforated liner. The size and shape of the

distance between the front compressor and the

holes are predetermined to admit the correct

rear turbine must be limited if critical shaft lengths

quantity of air at the velocity and angle required

are to be avoided. High torque is present if there

to control the flame pattern. Cutouts are provided

is a long shaft of small diameter.

in two of the bottom chambers for installation

Since the compressor and turbine are not

of the spark igniters. Notice in figure 1-28 how the

susceptible to shortening, shaft length limitation

combustion chambers are supported at the aft end

is absorbed by developing a new type of burner.

by matching outlet ducts in the turbine nozzle

The burner designers had to develop a design that

assembly.

would give the desired performance in much less

Figure 1-28 shows how the forward face of the

relative linear distance.

chambers presents size apertures that align with

The can-annular combustion chambers are

the six fuel nozzles of the corresponding fuel

arranged radially around the axis of the engine;

Figure 1-28.-Can-annular combustion chamber components and arrangement.

1-22