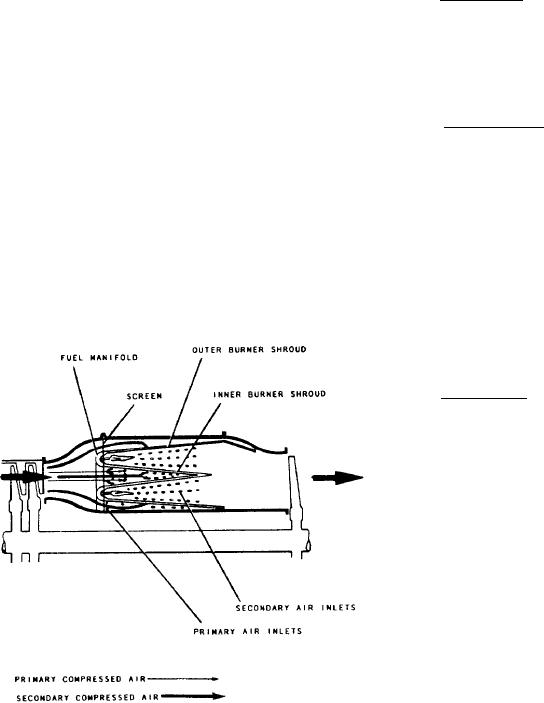

details of the liner. The liner consists of an

is divided by the proper holes. Louvers and slots

undivided circular shroud extending all the way

divide the main streams--primary and secondary

around the outside of the turbine shaft housing

air. The primary or combustion air is directed

(fig. 1-27). The chamber is constructed of one or

inside the liner at the front end, where it mixes

more baskets. If two or more chambers are used,

with the fuel and is burned. Secondary or cooling

they are placed one outside of the other in the

air passes between the outer casing and the liner

same radial plane. The double-annular chamber

and joins the combustion gases through larger

is shown in figure 1-27.

holes toward the rear of the liner. Combustion

gases are cooled from about 3,500F to about

The combustion chamber housing is made in

1,500F forward of the turbine. Holes are

three sections. These sections are the inlet, center,

provided to aid in atomization of the fuel. These

and rear sections.

holes are located around the fuel nozzle in the

The inlet section receives the air from the axial-

dome or inlet end of the liner. Louvers are also

flow compressor. This section is a diffuser. It

provided along the axial length of the liners to

slows the velocity of the air by providing a larger

direct a cooling layer of air along the inside wall

area just before the liner area, thus raising air

of the liner. This layer of air controls the flame

pressure. Also present is a coarse wire screen,

pattern by keeping it centered in the liner. This

whose function is to increase turbulence to aid in

air layer prevents the 3,000F temperatures of the

fuel atomization.

combusting gases from burning the liner walls.

The center section of the chamber housing

Figure 1-26 shows the flow of air through the

surrounds the liner, providing an outer wall for

louvers in the double-annular type of combustion

the axial path of the air. The center section

chambers.

provides the mounting pads for the installation

of fuel drain valves. The drain valves drain

Annular or Basket Type

residual or accumulated fuel out of the combus-

tion chamber after engine shutdown. This action

The annular combustion chamber, the type

p r e v e n t s afterfires or excessive starting

usually found in axial-flow engines, consists

temperatures during the next start. Located on the

basically of a housing and a liner, similar to the

bottom of the housing are the spring-loaded

can type. The difference lies in the construction

combustion chamber drain valves. These valves

drain automatically whenever internal chamber

pressures approach atmospheric pressure. This

fuel is drained to an overboard drain compart-

ment in the airframe.

The rear section converges to form a narrow

annulus. This type of construction speeds up

airflow before it enters the turbine section.

Fuel is introduced through a series of nozzles

at the upstream end of the liner. The fuel nozzles

are screwed into fuel manifolds, located within

two concentric fairings. If the chamber liner is of

double-annular construction, there are two fuel

manifolds. Only one manifold would be required

if it were of single-annular construction. The two

concentric fairings that support the fuel manifolds

also perform the function of dividing the entering

airflow into three concentric annular streams. The

outer stream is delivered to the space between the

combustion chamber liner and the chamber

housing. The middle stream is delivered to the

space between the inner and outer sections of the

liner. The inner stream is delivered to the space

between the liner and the rotor shaft housing. The

two concentric fairings are supported by radial

Figure 1-26.-Components and airflow of a double-annular

struts in the diffuser section.

combustion chamber.

1-20