ignition, and a fuel drainage system to drain off

dome. When internal mounting at the liner dome,

the chamber cover is removed for replacement or

unburned fuel after engine shutdown.

maintenance of the nozzle.

The three basic types of combustion chambers

The simplex nozzle, with its single orifice, does

are as follows:

not provide a satisfactory spray over a wide range

1. The multiple chamber, or can

of operating conditions. Therefore, its use on

2. The annular, or basket

current models of jet engines is limited.

The duplex nozzle has good spray character-

3. The can-annular

istics. Its use does require a pressurizing valve

Can Type

(flow-divider) to divide flow to the primary and

main fuel manifolds. During starting and idling,

The can-type combustion chamber is typical

the small primary orifice of the duplex nozzle

provides a high degree of atomization under low

of the type used on axial-flow engines. Can-type

pressures. As sufficient pressure builds, the

combustion chambers are arranged radially

around the axis of the engine. The amount of

pressurizing valve opens the main line; the larger

chambers will vary in number. In the past (or

orifice supplies increased fuel in a atomized form.

Newer engines use single-or multiple-unit duplex

development years) as few as 2 and as many as

nozzles for satisfactory sprays under various

16 chambers have been used. The present trend

shows the use of about 8 or 10 combustion

operating conditions.

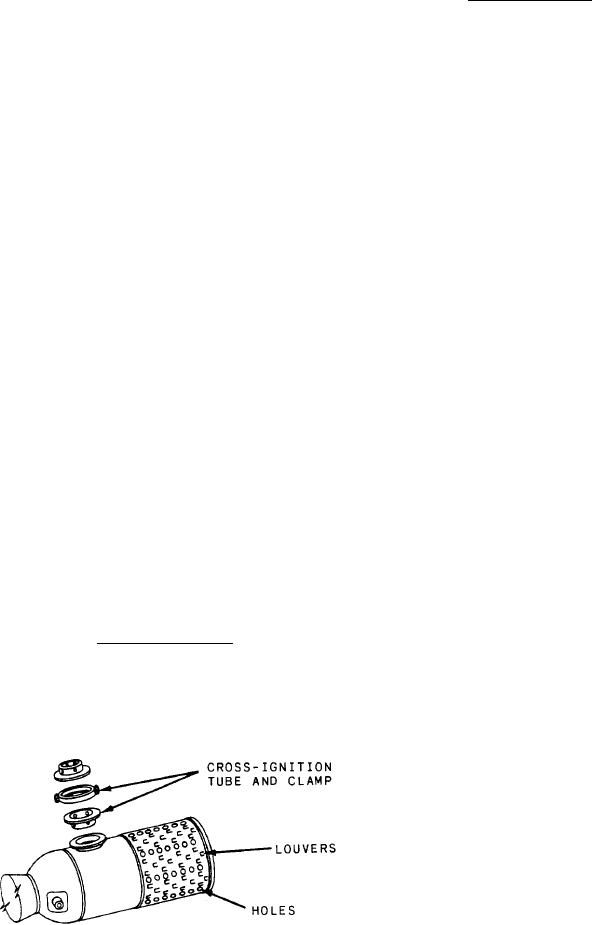

The cross-ignition tubes are a necessary part

chambers. Figure 1-25 shows the liner of a can-

type combustion chamber. These chambers are

of the can-type combustion chambers. Since each

numbered in a clockwise direction. As you face

of the cans is in reality a separate burner, each

operates independently of the other. Combustion

the rear of the engine and look forward, the

number 1 chamber is at the top.

is spread during the initial starting operation by

simply interconnecting all the chambers. As the

Some provision is made in the combustion

chamber case or in the compressor air outlet elbow

flame is started by the spark igniter plugs in the

for the installation of a fuel nozzle. The fuel

two lower chambers, it passes through the tubes

nozzle delivers the fuel into the liner in a finely

and ignites the combustible mixture in the

atomized spray. The finer the spray, the more

adjacent chambers. This process, similar to the

rapid and efficient the burning process.

action of a pilot light on a gas stove, continues

The two types of fuel nozzles being used in

until all the chambers are ignited. Actually only

the various types of combustion chambers are the

a few seconds are needed for this process. Then

simplex nozzle and the duplex nozzle. The fuel

the two spark igniters are no longer needed, and

nozzles are constructed so they can be installed

they cut off automatically.

in various ways. The two methods used most

To be sure the can-annular type combustion

frequently are external mounting and internal

chambers have positive ignition during the starting

mounting. In external mounting, a mounting pad

cycle, two spark igniters are used and located in

is provided for attachment of the nozzle to the

the two lower chambers.

case or the inlet air elbow, with the nozzle tip

Another very important requirement in the

projecting into the chamber liner, usually near the

construction of combustion chambers is providing

the means for draining unburned fuel. The

drainage requirement involves many factors, such

as the prevention of residual fuel deposits (gum)

after evaporation in the fuel manifold, nozzles,

and combustion chambers. Also, if fuel is allowed

to accumulate after shutdown, an afterfire could

occur. Another possibility is at the next starting

attempt, the excess fuel in the combustion

chamber could ignite. Tailpipe temperature could

go beyond safe operating limits.

The liners of the can-type combustors

(fig. 1-25) have the usual perforations of various

sizes and shapes. Each hole has a specific purpose

and effect on the flame propagation within the

Figure 1-25.-Cars-type combustion liner.

liner. The air entering the combustion chamber

1-19