blades. Some models of turboprop engines use as

section. It always has flanges to provide for the

front and rear bolting of the assembly to the

many as five turbine stages. You should remember

combustion chamber housing and the exhaust

that regardless of the number of wheels necessary

cone assembly, respectively. Figure 1-39 shows a

for driving engine parts, there is always a turbine

turbine casing.

nozzle in front of each wheel.

The occasional use of more than one turbine

EXHAUST SECTION

wheel is necessary in cases of heavy rotational

The exhaust section of the turbojet engine is

loads. Heavy loads that require multiple-stage

made up of several parts, each of which has its

turbine wheels often make it advantageous to

use multiple rotors. Shafts are bolted to the

individual functions. Although the parts have

appropriate turbine on one end and at the other

individual purposes, they also have one common

end to the unit requiring the rotative power.

function. They must direct the flow of hot gases

Typical of this situation are split compressors or

rearward in such a manner as to prevent

propellers, or a gas generator for helicopters, In

turbulence, while causing a high final or exit

velocity to the gases.

each of these situations, the turbine for each of

In performing the various functions, each of

the rotors may have one or more stages.

In the single-rotor turbine, shown in figure

the parts affects the flow of gases in different

1-23, the power is developed by one rotor. All

ways, as described in the following paragraphs.

The exhaust section is directly behind the

engine-driven parts are driven by this single wheel,

This arrangement uses engines where the need for

turbine section. It ends with the ejection of gas

low weight and compactness predominates. The

at the rear in the form of a high-velocity jet.

single-rotor turbine may be either single or

The parts of the exhaust section include the

multiple stage.

exhaust cone, tailpipe (if required), and the

In the multiple-rotor turbine, the power is

exhaust, or jet nozzle, Each of these parts is

developed by two or more rotors. It is possible

discussed individually so the exhaust section will

for each turbine rotor to drive a separate part of

be quite familiar to you.

the engine. For example, a triple-rotor turbine

The exhaust cone collects the exhaust gases

may be so arranged that the first turbine

discharged from the turbine assembly and

drives the rear half of the compressor and the

gradually converts them into a solid jet. During

accessories. The second turbine drives the front

this operation, the velocity of the gases will

half of the compressor, and the third turbine

decrease slightly, and the pressure will increase.

furnishes power to a propeller (fig. 1-38).

This is caused by the diverging passage between

The turbine rotor arrangement for a dual-

the outer duct and the inner cone. The annular

area between the two units increases rearward

rotor turbine, such as required for a split-spool

compressor, is similar to the arrangement in figure

(fig. 1-40).

1-38. The difference is in the use of the third

turbine for a propeller,

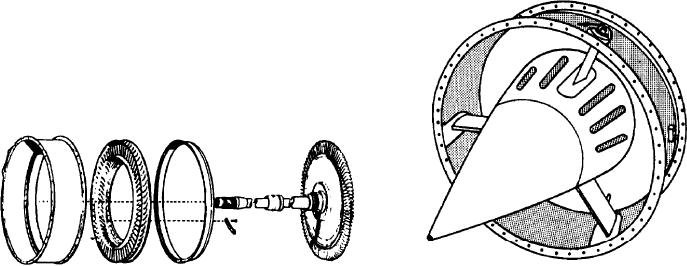

The remaining elements concerning the turbine

is the turbine casing or housing. The turbine

casing encloses the turbine wheel and the nozzle

vane assembly. It gives either direct or indirect

support to the stator elements of the turbine

Figure 1-40.-Exhaust collector and welded support status.

Figure 1-39.-Turbine casing assembly.

1-27