NOTE: The exhaust or jet nozzle

airframe. The nozzle attaches to

gives to the exhaust gases the all-

the rear of the tailpipe if there is a

important final boost in velocity.

need. It is attached to the rear

The jet nozzle, and the tailpipe, is

flange of the exhaust duct if a

not a part of the basic power

tailpipe is not necessary. There a re

plant, but is supplied as a part of

basically two types of jet nozzles--

the

fixed-area and variable-area.

There are two types of jet nozzle design. They

are the converging design, used on most freed-area

nozzles for subsonic velocities, and the converging-

diverging design, for supersonic gas velocities.

The fixed-area type is the simpler of the two jet

nozzles, since there are no moving parts. It is

attached to either a tailpipe or exhaust cone, and any

adjustment in nozzle area is mechanical.

Adjustments in a fixed-area nozzle are

sometimes necessary because the size of the exit

orifice will directly affect the operating temperature

of the engine. There are several ways to adjust a

fixed-area nozzle. One method is to trim or cut away

strips from the conical section of the exhaust nozzle.

Provided, of course, the temperature was too high. If

the inlet temperature is too low, a nozzle of less area

is used to replace the inadequate one.

Another method of reducing the nozzle area is to

use inserts. The inserts fit inside a joggled retainer

held in place by two screws.

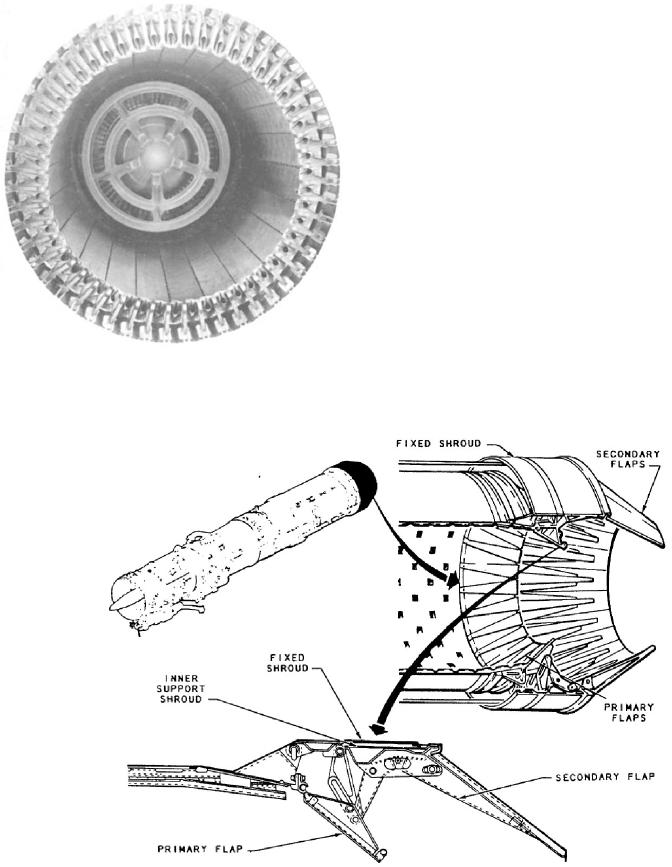

Figure 1-44.-Segment-type nozzle assembly.

Figure 1-45.-Variable exhaust nozzle assembly.

1-30