If the tool cannot be located, the person doing

the investigation will sign a lost tool statement and

the VIDS/MAF. The statement indicates that a

lost tool investigation was conducted and that the

tool was not found. After the investigation, follow

the normal VIDS/MAF completion process.

COMMON HAND TOOLS

In this chapter the term common hand tools

is used to refer to small, nonpowered hand tools

that are common to the AD rating. This term

includes such common tools as hammers, socket

sets, wrenches, screwdrivers, and pliers.

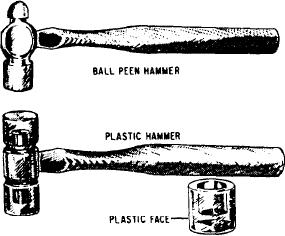

Figure 2-1.-Hammers.

Hammers

BALL PEEN HAMMER.-- The ball peen

hammer is sometimes referred to as a machinist's

Hammers are dangerous tools when used

carelessly and without consideration, Practice will

hammer. It is a hard-faced hammer made of

help the inexperienced to learn how to use a

forged tool steel.

hammer properly. Hold the handle near the end

The flat end of the head is called the face. This

with your fingers underneath and your thumb

end is used for most hammering jobs. The other

along the side or on top of the handle. Your

end of the hammer is called the peen. The peen

thumb should rest on the handle and never overlap

end is smaller in diameter than the face and is

your fingers. Oils on the face of the hammer will

useful for striking areas that are too small for the

cause it to glance off the work. Wipe the oil off

face to enter.

with a rag and rub the face with coarse sandpaper

or emery cloth. Never use a hammer that has a

Ball peen hammers are made in different

loose head or cracked handle. Most hammer

weights, usually 4, 6, 8, and 12 ounces and

accidents are caused by a loose head or a slippery

1, 1 1/2, and 2 pounds. For most work, a

handle. So remember these tips when using any

1 l/2-pound or a 12-ounce hammer will do.

kind of striking tool. Tighten the loose hammer-

head by driving a wedge in the end of the handle.

The wedge spreads the handle tightly inside the

MALLET.-- A mallet is a soft-faced hammer.

head. Do not strike a hardened steel surface with

Mallets are made with brass, lead, tightly rolled

a steel hammer. Small pieces of steel may break

strips of rawhide, and plastic heads, Sometimes

and injure someone or damage the work. Use a

the plastic head has a lead core for added weight.

soft hammer in striking hardened steel or highly.

Plastic mallets similar to the one shown in

polished stock. If a soft hammer is not available,

use a piece of copper, brass, lead, or wood to

figure 2-1 are the type normally found in your

protect the hardened steel. It is permissible to

toolbox. The weight of the plastic head may range

strike a punch or chisel directly with the ball-peen

from a few ounces to a few pounds. Use the

plastic mallet for straightening thin sheet ducting

hammer because the steel in the heads of punches

and chisels is slightly softer than that of the

or when installing clamps.

hammerhead.

There are various types of hammers, all of

which are used to apply a striking force where the

Socket Sets

force of the hand alone is insufficient. Each of

The socket set is one of the most versatile tools

these hammers has a head and a handle, even

in the toolbox. Basically, it consists of a handle

though these parts differ greatly from hammer to

hammer. So that you may have a better idea of

and a socket-type wrench that can be attached

to the handle. A complete socket wrench set

their differences and uses, let's consider the types

consists of several types of handles along with bar

of hammers used most frequently. See figure 2-1.

2-3