OPEN-END WRENCH.-- The jaws of the

open-end portion of the combination wrench are

machined at 15 degrees from parallel in respect

to the center line of the handle. This permits the

use of the wrench where there is room to make

only a part of a complete turn. If the wrench is

turned over after the first swing, it will fit on the

same flats and turn the nut farther. After two

swings on the wrench, the nut is turned far enough

so that a new set of flats are in position for the

wrench.

Use the open end of the combination wrench

on tubing nuts and in cramped places. Sometimes

the cramped space is too small for a socket or box-

end to be slipped over the nut or bolt head. When

using any open-end type wrench, always make

sure the wrench fits the nut or bolt head, and pull

on the wrench--never push. Pushing a wrench is

dangerous. The threads could break loose un-

expectedly and cause damage to adjacent equip-

ment or injury to the person using the wrench.

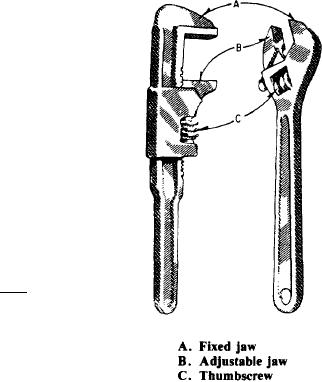

ADJUSTABLE WRENCHES.-- Adjustable

Figure 2-5.-Adjustable wrenches.

wrenches are not intended to replace open-end or

box-end wrenches, but they are useful in work-

ing in restricted areas. In addition, they can be

work will not allow all four steps to be followed,

adjusted to fit odd size nuts. Adjustable wrenches

are not intended for standard use but rather for

select another type of wrench for the job.

emergency use. The wrenches were not built for

Adjustable wrenches should be cleaned in a

solvent, and a light oil applied to the thumbscrew

use on extremely hard-to-turn items. As shown

in figure 2-5, adjustable wrenches have a fixed jaw

and the sides of the adjustable jaw. They should

(A) and an adjustable jaw (B), which is adjusted

also be inspected often for cracks, which might

by a thumbscrew (C). By turning the thumbscrew,

result in failure of the wrench.

the jaw opening may be adjusted to fit various

sizes of nuts. The size of the wrenches ranges from

Screwdrivers

4 to 18 inches in length. The maximum jaw open-

ings vary in direct proportion to the length of the

Two basic types of screwdriver blades are

handle.

used: the common blade for use on conventional

Adjustable wrenches are often called "knuckle

slotted screws, and a crosspoint blade for use on

the recessed head Phillips or Reed and Prince type

busters" because mechanics frequently suffer the

of screws. See figure 2-6. The common and cross-

consequences of improper usage of these tools.

There are four simple steps to follow in using

point blade types are used in the design of various

special screwdrivers, some of which are also

these wrenches. First, choose one of the correct

shown in figure 2-6.

size. Do not pick a large 12-inch wrench and

adjust the jaw for use on a 3/8-inch nut. This

COMMON SCREWDRIVERS.-- The com-

could result in a broken bolt and a bloody hand.

Second, be sure the jaws of the correct size wrench

bination length of the shank and blade identifies

are adjusted to fit snugly on the nut. Third,

the size of common screwdrivers. They vary from

2 1/2 to 12 inches. The diameter of the shank and

position the wrench around the nut until the nut

the width and thickness of the blade tip, which

is all the way into the throat of the jaws. If not

fits the screw slot, are in proportion to the length

used in this manner, the result is apt to be as

of the shank. The blade is hardened to prevent

bloody as before. Fourth, pull the handle toward

it from being damaged when it is used on screws.

the side having the adjustable jaw. This will

It can easily be chipped or blunted when used for

prevent the adjustable jaw from springing open

other purposes. The blade of a poor quality

and slipping off the nut. If the location of the

2-6