nut to the point where it turns easily, move the

handle into the vertical position, and then turn

the handle with your fingers.

SLIDING T-BAR HANDLE.-- While using

the sliding bar on the T-handle, the head can be

positioned at either the end or the center of the

sliding bar. Select the position that is needed for

the job at hand.

SPEED HANDLE.-- After the nuts are

loosened with the sliding bar handle or the ratchet

handle, the speed handle will help remove the nuts

in a hurry. In many instances, the speed handle

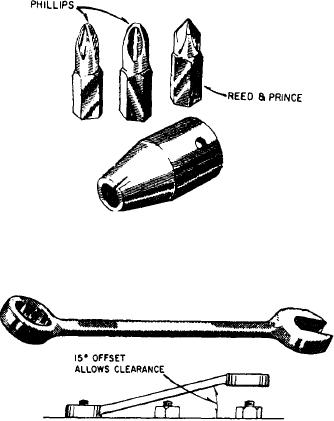

Figure 2-3 .-Screwdriver adapter.

is not strong enough to be used for breaking loose

or tightening. Use the speed socket wrench

carefully to avoid damaging the nut threads.

ACCESSORIES.-- Several accessory items

complete the socket wrench set. Extension bars

of different lengths are made to extend the handles

to any length needed. A universal joint allows the

nut to be turned with the wrench handle at an

angle. A universal socket is also available, and

universal socket joints, bar extensions, and

universal sockets in combination with appropriate

Figure 2-4 .-Combination wrench.

handles make it possible to form a variety of tools

that will reach otherwise inaccessible nuts and

BOX-END WRENCH.-- The box-end fits

bolts.

completely around the nut or bolt head. The

Another accessory item that comes in handy

is an adapter, which allows you to use a handle

box-end is usually constructed with 12 points. The

having one size drive with a socket having a

advantage of the 12-point construction is that the

wrench will operate between obstructions where

different size drive. For example, a 3/8- by

space for the swing angle is limited. A very short

1/4-inch adapter would make it possible to turn

swing of the handle will turn the nut far enough

all 1/4-inch-square drive sockets with any

3/8-inch-square drive handle.

to allow the wrench to be lifted and the next set

There are special sockets that are used to adapt

of points to be fitted to the corners of the nut.

various types of screwdriver bits to a speed handle.

It is possible to use this wrench in places where

the swing angle is limited to as little as 30 degrees.

See figure 2-3. This socket-type screwdriver is used

to remove recessed head screws from access panels

The box-end portion of the wrench is designed

on equipment.

with an offset in the handle. Notice in figure 2-4

how the 15-degree offset will allow clearance over

nearby parts. One of the best features of the box-

Combination Wrenches

end is that there is little or no chance that the

Most toolboxes contain a set of combination

wrench will slip off the nut or bolt. However,

wrenches. As shown in figure 2-4, the combina-

there is the disadvantage of slow work with the

tion wrench has an open-end wrench on one end

box-end of the combination wrench. Each time

and a box-end (of the same size) on the other end.

the wrench is backed off, it has to be lifted up

For speed and light stress operations, use the

and refitted to the head of the work. To save time,

use the nonslip box-end of the wrench to break

open-end. Then switch to the box-end for safety

loose tight bolts or to snug up work after the bolt

under stress. For ease of explanation, each end

of the wrench is discussed separately. Adjustable

has been seated with a faster type of wrench that

wrenches are also briefly discussed.

might slip under stress.

2-5