replacing whenever necessary to keep them in

good condition. Some of the aircraft parts that

require bonding are identified below.

Control surfaces. Each control surface should

apply to trim tabs.

Engine mounts. Use at least four bonding

jumpers across each engine mount support. This

provides a current path between the engine mount

and aircraft structure.

E n g i n e cowling. Use at least four sym-

metrically placed bonding jumpers to bond the

engine ring cowling to the engine across the rubber

mounts at the front end of the cowling.

Equipment mounts. Place bonding jumpers

across shock mounts supporting electrical and

radio equipment and the instrument panel.

Methods and Materials

You should install bonding connections so

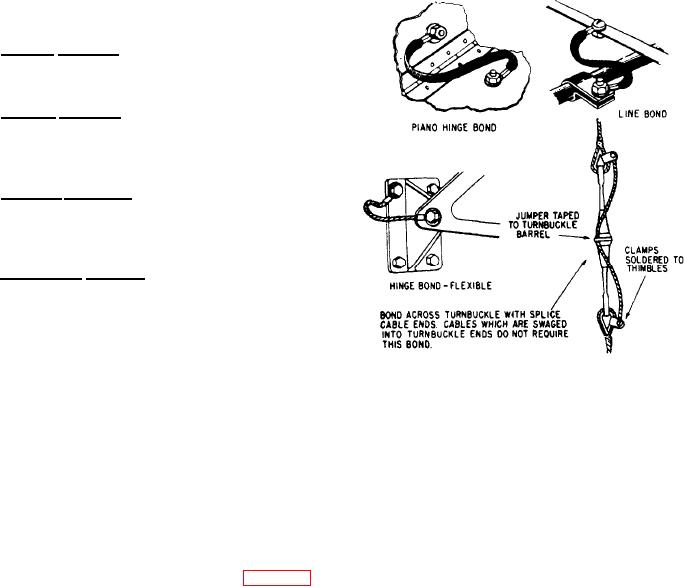

Figure 2-23.-Bonding methods.

they won't break or loosen. This prevents a

variation in the resistance during movement. One

primary objective for bonding is to provide an

CABLE LACING AND TYING

electrical path of low dc resistance and low RF

impedance; therefore, it is important that the

Wire groups and bundles are laced or tied to

jumper be a good conductor of ample size. Make

provide ease of installation, maintenance, and

the bonding wire as short as possible. Bond parts

inspection. Lacing or tying keeps cables neatly

directly to the basic aircraft structure rather than

secured in groups and avoids possible damage

through other bonded parts, insofar as practical.

from chafing against equipment or interference

Install bonding jumpers so they do not interfere

with equipment operation.

with aircraft movable components. (See fig. 2-23.)

You tie a group or bundle of wires by using

Contact of dissimilar metals in the presence

individual pieces of cord tied around the group

of an electrolyte, such as salt water, produces an

or bundle at regular intervals. You lace a bundle

electric action (battery action), which causes

or group of wires by securing them together inside

corrosion in the connection. The intensity of this

enclosures by a continuous piece of cord. You use

electric action varies with the kinds of metals.

this cord to form loops (half hitches) at regular

Bonding frequently causes the direct contact of

intervals around the group or bundle.

Cotton, nylon, or fiber glass cord are used to

dissimilar metals. In such cases, the metals used

are of the kind that produce minimum corrosion.

tie or lace. The cotton cord has a wax coating to

make it resist moisture and fungus.

You should make connections so that if there is

corrosion, its in replaceable elements such as

jumpers, washers, or separators.

SLEEVING

Don't use self-tapping screws for bonding

purposes. Jumpers shouldn't be compression-

Sleeving helps protect connections from

fastened through plywood or other nonmetallic

accidental shorting and moisture and to lengthen

the arc-over path between contacts. Don't use

material. When you are performing a bonding

operation, clean the contact surfaces of insulating

insulating sleeves on connections or connectors

finishes or surface films before assembling. After

that require moistureproofing. Don't use sleeving

installation, refinished the assembly with a

on connectors that have a sealing grommet that

suitable protective finish. You should refer to

covers the soldered connection.

NAVAIR 01-1A-505 for detailed information

Sleeving, commonly called spaghetti, has

many applications in naval aviation. Some of the

about bonding procedures.