insert, which holds the current-carrying contacts.

The plug usually attaches to the cable end and is

the part of the connector on which the coupling

nut mounts. The receptacle is the half of the

connector to which the plug connects. The

receptacle is usually mounted on a part of the

equipment.

In naval aircraft, connectors with crimp-type

contacts are widely used. Maintenance is easier

because you can remove the contact from the

connector. If the connector is damaged, you can

remove the contacts and replace the connector

shell. If just a connector pin is damaged, you can

remove and replace the pin. This is a considerable

advantage over the solder-type connector, both

in convenience and time savings. A discussion of

the special tools you need to remove and insert

crimped contacts is contained in Installation

Practices Aircraft Electric and Electronic Wiring,

NAVAIR 01-1A-505.

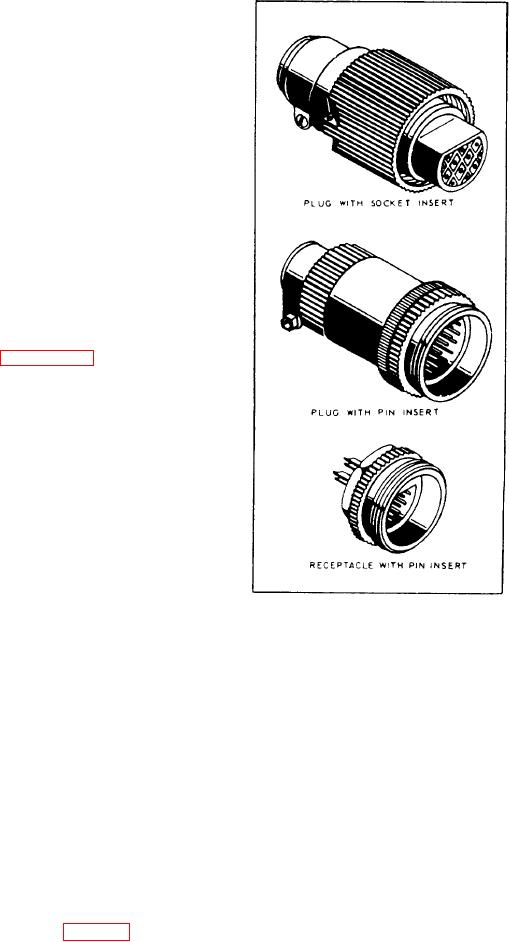

Some common types of subminiature con-

nectors are shown in figure 2-16. They are

used on instruments, switches, transformers,

amplifiers, relays, etc.

FABRICATION OF CABLES

Occasionally, you will have to make a cable

using connectors. The type of connector you will

use is specified in the MIM for the particular

aircraft. The following steps outline the procedure

you should use to make a cable:

1. Disassemble the connector to allow access

to the terminals. Devise a way to hold the

connector so both hands are free.

Figure 2-16.-Subminiature connectors.

2. Cut the cables to the correct length.

3. Strip the wire end with a wire stripper or

knife. If you use a knife, avoid cutting or

bottom connection and work left to right,

nicking the wire strands. Tin the bare wire

moving up a row at a time. After soldering the

end.

connections, the shields, if used, are soldered to

4. Run the wires through the connector

a common terminal or ferrule. Then lace the cable

assembly and coupling nuts.

and reassemble and moistureproof the connector,

5. Make sure all surfaces are clean.

if necessary. Fabricating instructions are con-

6. Flow rosin-core solder into the connector

tained in NAVAIR 01-1A-505.

terminals.

7. Hold the tip of the soldering iron against

MOISTUREPROOFING

the terminal. As the solder melts, push the

wire into the cavity. Hold the wire steady

Present Navy practice is to use potted

while the solder cools.

connectors (moistureproof or environmentproof

connectors). All jet- and carrier-type aircraft

When you solder, be careful not to injure the

have potted connectors. On other aircraft, use

connector insulation with the soldering iron.

moistureproofing sealant on electrical connectors

Follow a prearranged sequence (fig. 2-17). The

in areas where a chance of failure exists. All

recommended sequence is to start from the