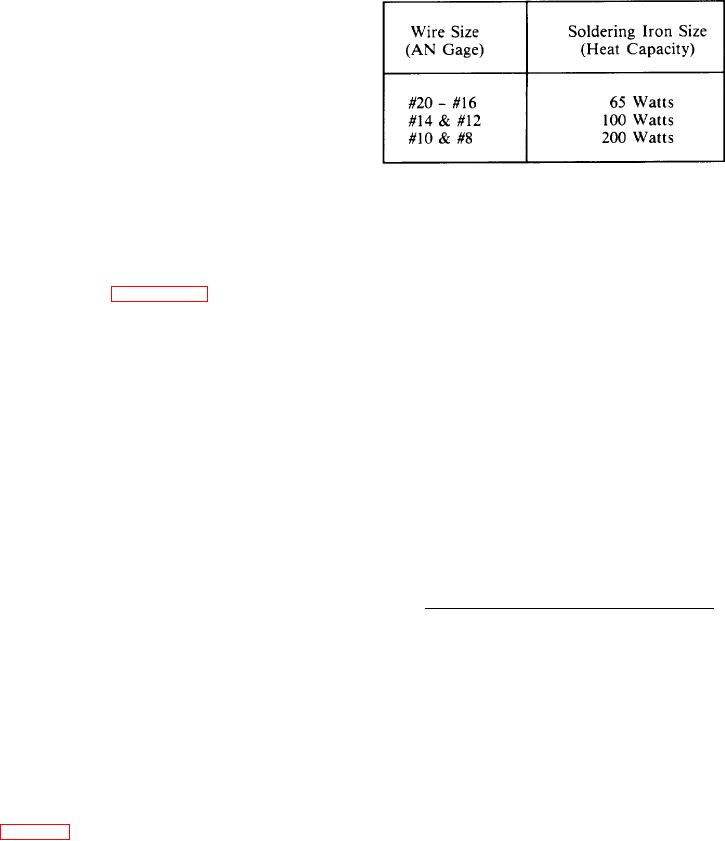

Table 2-3.--Approximate Soldering Iron Size for Tinning

The operation of this basic tool is efficient and

effective and extremely simple. To operate it,

insert the wire end in the proper direction to the

depth to be stripped. Now position the wire so

it rests in the proper groove for that size wire, and

squeeze.

Heat-shrinkable tubing is a plastic-like tubing

(similar to insulation sleeving) that will shrink to

a smaller diameter with proper heating. Place the

tubing over the joint, terminal, or part needing

insulation. Now apply heat with a heat gun, oven,

or other appropriate heat source. When the tubing

reaches a specific temperature (shrink temperature

REVIEW SUBSET NUMBER 4

depends upon the type of tubing), it quickly

shrinks around the object, forming a snug

Q1. What type of wire should you use to carry

jacket. In addition to being an insulator, the

600 to 1,000 volts with a temperature rating

shrinkable tubing helps relieve strain and adds

between 302F to 500F?

waterproofing. Figure 2-14 gives some of the

typical uses of heat-shrinkable tubing.

Q2. What type of metal used in wire forms a

SOLDERING

resistant oxide film on all its surfaces?

Wires are soldered to form a continuous and

permanent metallic connection, having a constant

electrical value. When soldering, strive for

Q3. W h e n stamping wire identification

superior workmanship. If you are sloppy, you

numbers, at what interval should you stamp

create problems and compound difficulties in

the wire?

system troubleshooting techniques. Study and

refer to NAVAIR 01-1A-505 when you are

soldering.

Q4. In wire identification numbers, the suffix

The most important part of soldering is the

N means the wire completes the circuit to

selection of the correct iron for the job. Soldering

irons are available in wattage ranges from 20 to

.

500 watts. Use irons with wattage ratings of 60,

100, and 200 watts for general work in aircraft

electrical wiring. Use pencil irons with a rating

of 20 to 60 watts for soldering small parts, The

Q5. What is the most important item to consider

soldering iron for printed circuit soldering is a

when soldering?

lightweight, 55-watt iron with a 600F (316C)

Curie point tip control. This iron has a three-wire

cord, which prevents leakage currents that could

damage the printed circuits.

AIRCRAFT ELECTRICAL

When soldering, you should select a soldering

HARDWARE

iron with a thermal capacity high enough so the

heat transfer is fast and effective. (Refer to

Learning Objective: Recognize uses for

table 2-3.) An iron with excessive heat capacity

and characteristics of aircraft electrical and

will burn or melt wire insulation. One with too

mechanical hardware.

little heat capacity will make a cold joint in which

the solder does not alloy with the work.

You shouldn't always use the same mounting

parts that you removed from the installation.

A soldering iron should also suit the

Before reusing the parts, inspect them to make

production rate. Do not select a small pencil iron

sure they aren't defective or damaged. Also check

where you need a high steady heat flow.