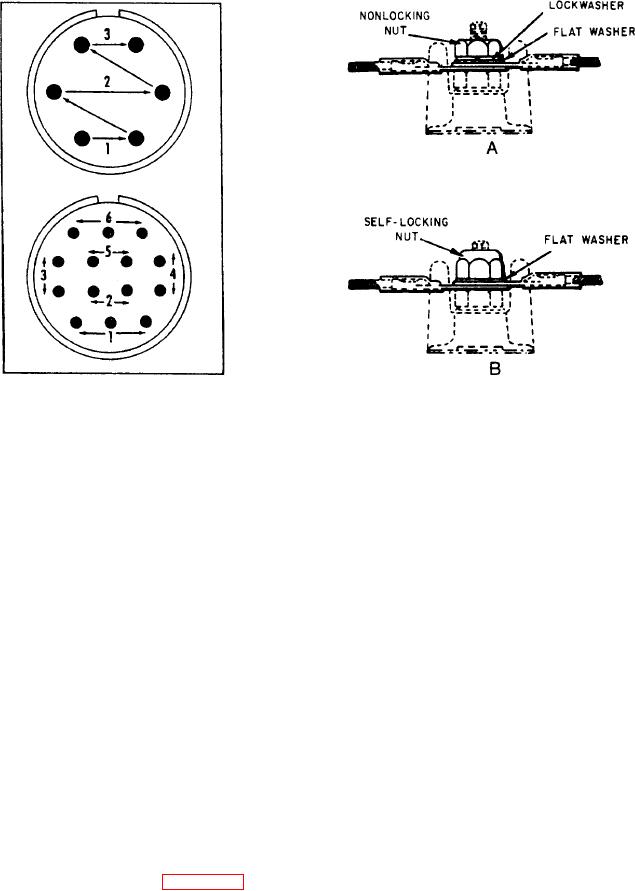

Figure 2-17.-Connector soldering sequence.

Figure 2-18.-Installation of cable terminals on terminal

block.

connectors in wheel wells, wing fold areas, engine

areas, engine nacelles, or cockpit decks have a

is especially desirable in areas of high vibration.

high chance of failure and are sealed. In addition,

In both installations, a requirement exists for the

moistureproof all connectors that interconnect

use of a flat washer, as shown in the drawing.

flight/basic navigation equipment.

Vibration and lateral pressure fatigue wires

Each terminal board in the aircraft electrical

system is identified by the letters TB followed by

at the solder cup. Moistureproofing reduces

the number of the individual board. Each stud

electrical connector failures by reinforcing the

wires against vibration and lateral pressure.

on the terminal board is identified by a number.

The sealing compound also protects electrical

The lowest number in the series starts at the end

nearest the terminal board identification number.

connectors from corrosion and contamination by

The identification number is on the structure to

excluding metallic particles, water moisture, and

which the terminal board attaches. It mounts on

aircraft liquids. One result of the connector's

better dielectric characteristics is the reduced

any identification strip cemented to the structure

chance of arc-over between pins.

under the terminal board. When replacing a

terminal board, don't remove the identifica-

TERMINAL BLOCKS

tion marking. If the identification marking is

damaged, replace it with one that is the same as

Terminal blocks, made from an insulating

the original.

material, support and insulate a series of terminals

from each other, as well as from ground. They

provide a way to install terminals within junction

JUNCTION BOXES

boxes and distribution panels.

The two methods of attaching cable terminals

Junction boxes accommodate electrical

terminals or other equipment. Individual junction

to terminal blocks are shown in figure 2-18. View

boxes are named according to their function,

A uses a standard nonlocking nut. In this

location, or equipment with which they are

installation method, the use of a lockwasher is

associated. Junction boxes have a drain hole

necessary. View B shows the preferred method.

(except boxes labeled "vaportight") at the lowest

When using an anchor nut, or self-locking nut,

point to drain water, oil, condensate, or other

you omit the lockwasher. The use of anchor nuts