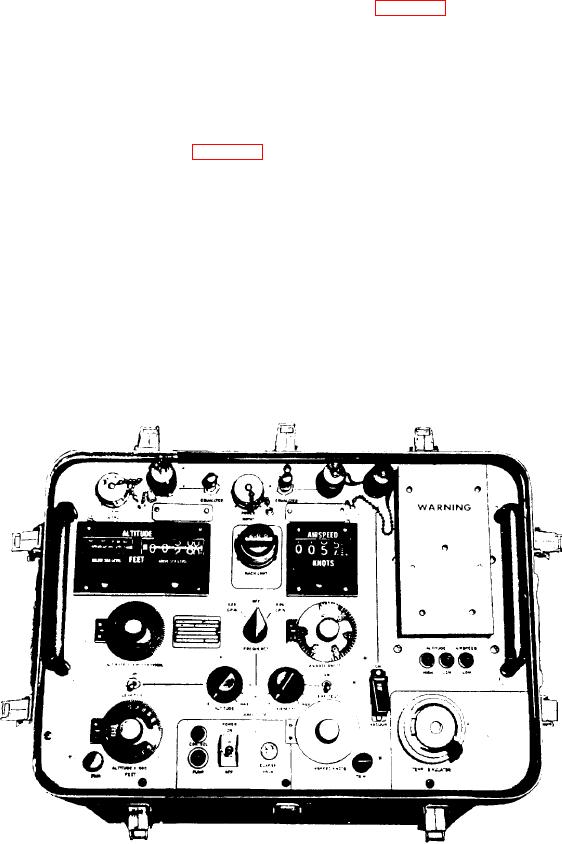

front panel of the test set. All the components are

of input settings and error amplification of

on the underside of the control panel. This

incremental gain comparison. It also avoids

makes the subassemblies and components easily

the chance of error in calculating the gain

accessible when the panel is not in it's carrying

factor.

case. The test set simulates airspeed and altitude

information, which is displayed on the front

For complete instructions on this tester, you

panel. See table 2-6 for test set particulars.

should refer to the current Operation and Service

Instruction Manual, NA 17-15CFA-2.

The test set has the following five capabilities:

1. It performs overall system checks on the

following equipment, pneumatic systems, air data

PRESSURE-TEMPERATURE TEST

systems, flight instruments, and pneumatic

SET TTU-205C/E

ancillary equipment. This equipment may be

either installed in or removed from the air-

The pressure-temperature test set (fig. 2-36)

craft.

provides regulated pitot and static pressure for

checking performance characteristics of aircraft

2. It provides simulated total temperature for

pneumatic instruments, air data systems, and

the USAF MA-1 Probe, a platinum resistance

other auxiliary equipment. You can also conduct

sensing element whose resistance is 50.0 ohms at

dynamic tests, quantitative calibration tests,

0C.

pneumatic-system leak tests, and total tempera-

ture probe tests using this tester.

3. It connects directly into the aircraft's

pneumatic system to measure and control static

The TTU-205C/E is a compact assembly. It

pressure (Ps) and pitot pressure (PT).

consists of a control panel, components assembly,

and combination carrying case with removable

4. It accepts electrical power from an external

cover. All the controls, indicators, switches,

source.

electrical, and pneumatic connectors are on the

Figure 2-36.-Test Set, TTU-205C/E.