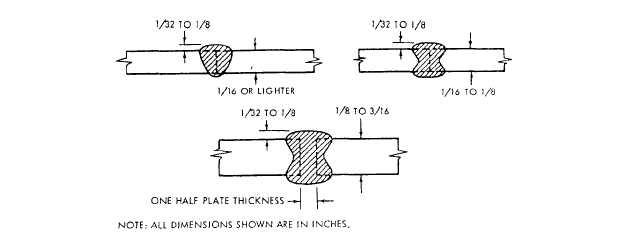

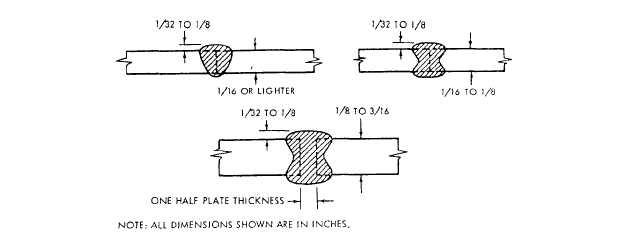

Figure 15-36.—Butt joints in light sections.

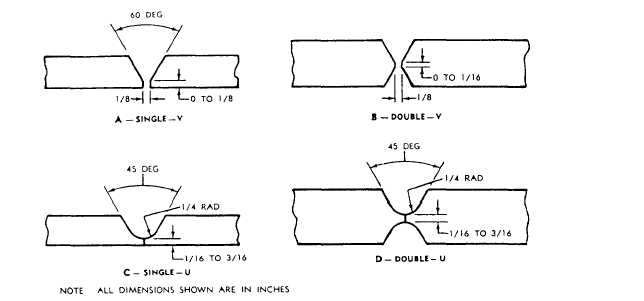

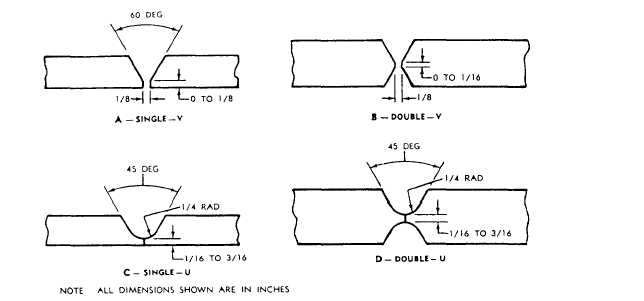

Figure 15-37.—Butt joints in heavy sections.

The preparation of the metal for welding is

governed by the form, thickness, kind of metal, the load

that the weld will be required to support, and the

available means for preparing the edges to be joined.

The five basic types of welded joints arc the butt,

tee joints, lap, edge, and corner. (See figure 15-35.)

BUTT JOINTS.—A butt joint is made by placing

two pieces of material edge to edge so there is no

overlapping, and then welding them together. Plain,

square butt joints used for butt welding thin sheet metal

are shown in figure 15-36. Butt joints for thicker metals,

with several types of edge preparation, are shown in

figure 15-37. These edges can be prepared by flame

cutting, shearing, flame grooving, machining, or

grinding.

Plate thicknesses of 3/8 to 1/2 inch can be welded

by using the single-V or single-U joints, as shown in

views A and C of figure 15-37. The edges of heavier

sections should be prepared as shown in views B and D

of figure 15-37. The single-U groove is more

satisfactory and requires less filler metal than the

single-V groove when welding heavy sections and when

welding in deep sections. The double-V groove joint

requires approximately one-half the amount of filler

metal used to produce the single-V groove joint for the

same plate thickness. In general, butt joints prepared

from both sides permit easier welding, produce less

distortion, and ensure better weld qualities in heavy

sections than joints prepared from one side only.

15-27