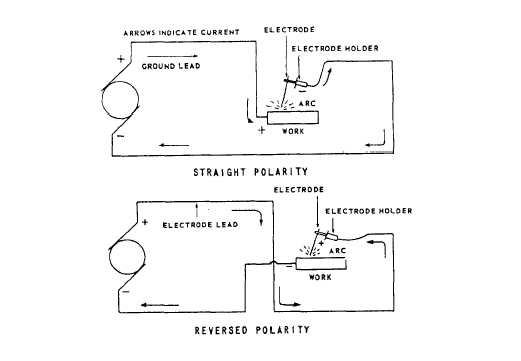

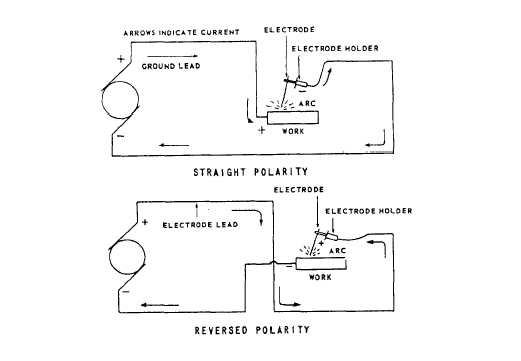

Figure 15-43.—Straight and reverse polarity in electric welding.

joined more easily with ac current, while others get

better results when dc current is used.

Welding Currents

With direct current the welding circuit may be either

dc straight polarity (DCSP) or dc reverse polarity

(DCRP). When the machine is set for straight polarity,

the flow of electrons is from the electrode to the plate,

which creates considerable heat in the plate. In reverse

polarity, the flow of electrons is from the plate to the

electrode, thus causing a greater concentration of heat

at the electrode. See figure 15-43. The intense heat at

the electrode tends to melt off the end of, the electrode

and may contaminate the weld. Hence, for any given

current, dc reverse polarity requires a larger diameter

electrode than dc straight polarity. For example, a

1/16-inch diameter tungsten electrode normally can

handle about 125 amperes in a straight polarity circuit.

However, if reverse polarity is used with this amount of

current, the tip of the electrode will melt off.

Consequently, a 1/4-inch diameter electrode will be

required to handle 125 amperes of welding current.

Polarity also affects the shape of the weld. Straight

polarity produces a narrow, deep weld, whereas reverse

polarity with its larger diameter electrode and lower

current forms a wide and shallow weld. Therefore, dc

straight polarity is used for welding most metals because

better welds are achieved. With the heat concentrated at

the plate, the welding process is more rapid, and there

is less distortion of the base metal.

Alternating current, high-frequency (ACHF)

welding is a combination of dc straight polarity and dc

reverse polarity. One half of the complete ac cycle is

DCSP and the other half is DCRP. Unfortunately,

oxides, scale, and moisture on the work piece often tend

to prevent the full flow of current in the reverse polarity

direction. If no current whatsoever flowed in the reverse

polarity direction during a welding operation, the partial

or complete stoppage of current flow would cause the

arc to be unstable and sometimes go out. To prevent this,

ac welding machines incorporate a high-frequency

current flow unit. The high-frequency current is able to

jump the gap between the electrode and the work piece,

piercing the oxide film and forming a path for the

welding current to flow.

15-31