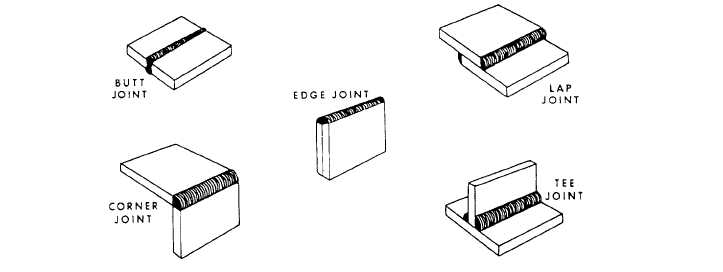

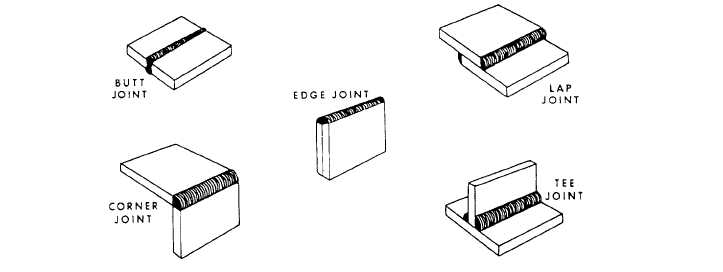

Figure 15-35.—Types of welded joints.

commonly used joints. Notice that the corner joint and

butt joint are classified as groove welds, while the tee

and lap joints are classified as fillet welds.

Welding is always done in the flat position

whenever possible. The puddle is much easier to control,

and the welder can work longer periods without tiring.

Quite often it is necessary to weld in the overhead,

vertical, or horizontal position in equipment repair.

The flat position is used when the material is to be

laid flat or almost flat and welded on the topside. The

welding torch is pointed downward toward the work.

This weld may be made by either the forehand or

backhand technique.

The overhead position is used when the material is

to be welded on the underside, with the torch pointed

upward toward the work. In welding overhead, you can

keep the puddle from sagging if you do not permit it to

get too large or assume the form of a large drop. The rod

is used to control the molten puddle. You should not

permit the volume of flame to exceed that required to

obtain a good fusion of the base metal with the filler rod.

Less heat is required in an overhead weld because the

heat naturally rises.

The horizontal position is used when the line of the

weld runs horizontal across a piece of work, and the

torch is directed at the material in a horizontal or near

horizontal position. The weld is made from right to left

across the plate (for the right-hand welder). The flame

is inclined upward at an angle of 45° to 65°, and the weld

is made with a normal forehand technique. Adding the

rod to the top of the puddle will prevent the molten metal

from sagging to the lower edge of the bead. If the puddle

is to have the greatest possible cohesion, it should not

be allowed to get too hot.

In a vertical weld, the pressure exerted by the torch

flame must be relied upon to a great extent to support

the puddle. It is important to keep the puddle from

becoming too hot, and to prevent the hot metal from

running out of the puddle onto the finished weld. It may

be necessary to remove the flame from the puddle for

an instant to prevent overheating, and then return it to

the puddle. Vertical welds are begun at the bottom, and

the puddle is carried upward with a forehand motion.

The tip should be inclined from 45° to 60°, the exact

angle depending upon the desired balance between

correct penetration and control of the puddle. The rod is

added from the top and in front of the flame with a

normal forehand technique.

Welded Joints

The properties of a welded joint depend partly on

the correct preparation of the edges being welded. All

mill scale, rust oxides, and other impurities must be

removed from the joint edges or surfaces to prevent their

inclusion in the weld metal. You should prepare the

edges to permit fusion without excessive melting, and

you should take care to keep to a minimum the heat loss

due to radiation into the base metal from the weld. A

properly prepared joint will give a minimum of

expansion on heating and a minimum of contraction on

cooling.

15-26