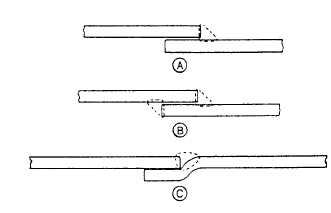

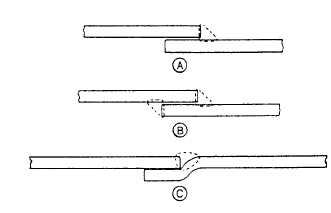

Figure 15-40.—Lap joints.

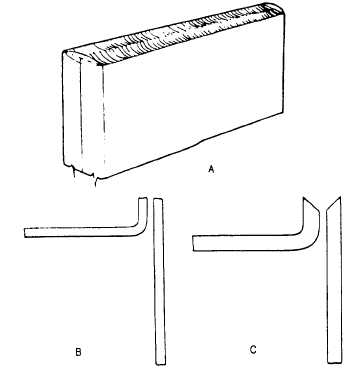

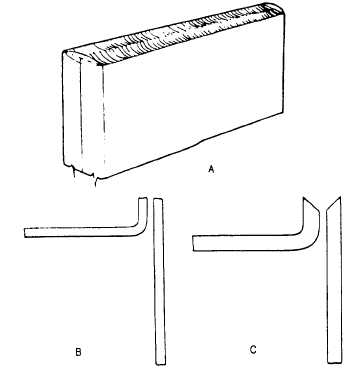

Figure 15-41.—Edge joints for light sheets and plates.

welded in the same plane. his type of joint is stronger

than the single lap type, but is more difficult to prepare.

EDGE JOINTS.—Edge joints are used to join two

or more parallel or nearly parallel members. Edge joints

are not very strong, and are used to join edges of sheet

metal, reinforcing plates in flanges of I-beams, and for

edges of angles. Two parallel plates are joined together,

as shown in view A of figure 15-41. On heavy plates,

sufficient filler metal is added to fuse or melt each plate

edge completely and to reinforce the joint.

Light sheets are welded as shown in view B of figure

15-41. No preparation is necessary other than to clean

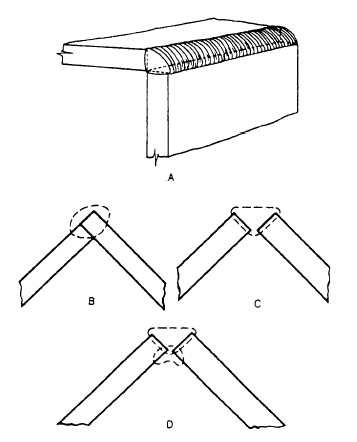

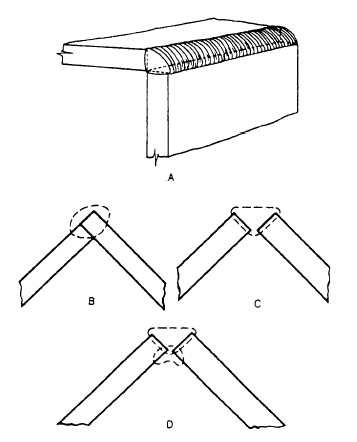

Figure 15-42.—Corner joints for sheets and plates.

the edges and tack weld them in position. The edges are

fused together so no filler metal is required. The heavy

plate joint, as shown in view C of figure 15-41, requires

that the edges be beveled to secure good penetration and

fusion of the side walls. Filler metal is used in this joint.

CORNER JOINTS —Corner joints are used to join

two members located approximately at right angles to

each other in the form of an L. The fillet weld corner

joint (view A of fig. 15-42) is used in the construction

of boxes, box frames, and similar fabrications.

The closed corner joint (view B of fig. 15-42) is used

on lighter sheets when high strength is not required at

the joint. In making the joint by oxyacetylene welding,

the overlapping edge is melted down, and little or no

filler metal is added. When the closed joint is used for

heavy sections, the lapped plate is V-beveled or

U-grooved to permit penetration to the root of the joint.

The open corner joint (view C of fig. 15-42) is used

on heavier sheets and plates. The two edges are melted

down, and filler metal is added to fill up the corner.

Corner joints on heavy plates are welded from both

sides, as shown in view D of figure 15-42. The joint is

15-29