CHAPTER 5

HOSE FABRICATION AND MAINTENANCE

Chapter Objective: Upon completion of this chapter, you will have a working

knowledge of the fabrication and maintenance of aircraft hydraulic and pneumatic

hoses and their associated hardware.

You are responsible for maintaining a portion of

the hundreds of feet of fluid and air lines and various

hardware and seals found in modern-day aircraft. The

maintenance of these lines frequently involves

fabrication and replacement of hose and hose

assemblies. To be able to select the proper type of

hose and hose assemblies and their hardware, you will

need a basic knowledge of the type, size, and material

from which items are to be made.

HOSE AND HOSE ASSEMBLIES

Learning Objective:

Identify the various

types of hose, hose assemblies, hardware,

tools, and equipment used on naval aircraft.

Hose assemblies are used to connect moving parts

with stationary parts and in locations subject to severe

vibration.

Hose assemblies are heavier than

aluminum-alloy tubing and deteriorate more rapidly.

They are used only when absolutely necessary. Hose

assemblies are made up of hose and hose fittings. A

hose consists of multiple layers of various materials.

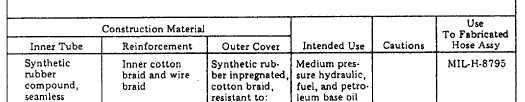

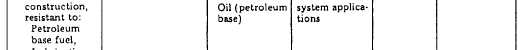

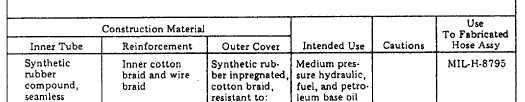

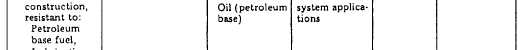

An example of the hose most often used in

medium-pressure applications is shown in figure 5-1.

TYPES OF HOSE

There are two basic types of hose used in military

aircraft and related equipment. They are synthetic

rubber and polytetrafluoroethylene, commonly

known as Teflon@ or PTFE.

Bulk hose identification will vary with the

materials from which the hose is constructed. It is

important that you are able to clearly identify the

proper hose to be used by recognizing the various

hose markings.

Figure 5-1.—Medium pressure synthetic rubber hose, MIL-H-8794.

5-1