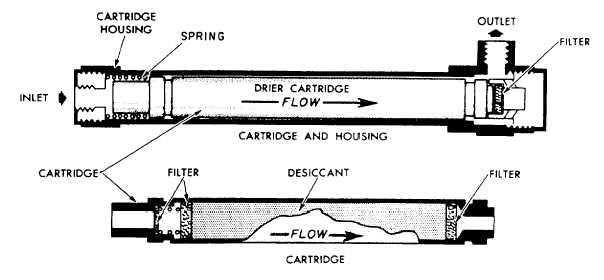

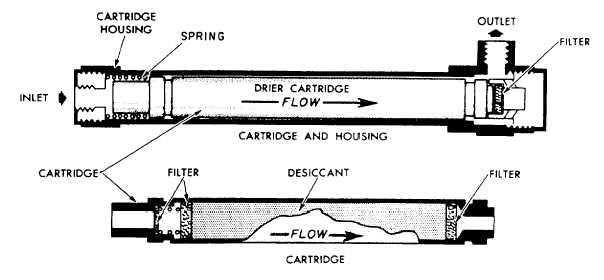

Figure 7-8.—Chemical air drier.

shows a hydraulic power system with an

air-pressurized reservoir incorporated. This system is

similar to the one found on many aircraft; however,

for clarification in the discussion of the operation of

the system, we have deleted some components

between the reservoir and the pump.

The reservoir is cylindrical in shape and has a

piston installed internally to separate the air and fluid

chambers. The piston rod end protrudes through the

reservoir end cap and indicates the fluid quantity. The

quantity indication may be seen by inspecting the

distance the piston rod protrudes from the reservoir

end cap. The reservoir has threaded openings for the

connection of fittings and components. The

schematic shown in figure 7-7 shows several

components installed in lines leading to and from the

reservoir; however, this may not be the case in the

actual installation. The air relief valve, bleeder valve,

etc., may be installed directly on the reservoir.

Because the reservoir is pressurized, it can

normally be installed at any attitude and still maintain

a positive flow of fluid to the pump.

CHEMICAL AIR DRIER.—Chemical air driers

are installed in air systems to absorb moisture that

may collect from air entering the system. The main

parts of the air drier, shown in figure 7-8, are the

housing, desiccant cartridge, filter (porous bronze),

and the spring.

To ensure proper filtering, the air

must pass through the air drier in the proper direction.

The correct direction of flow is indicated by an arrow

and the wordflow printed on the side of the cartridge.

Preventive maintenance of this component

consists of replacing the cartridge when it becomes

saturated. Maintenance should be accomplished in

accordance with instructions provided in the

applicable maintenance instruction manual (MIM).

AIR

PRESSURE

REGULATORS.—Air

pressure used in pressurizing hydraulic reservoirs

must be controlled within safe limits.

Specific

pressure requirements vary between aircraft. In some

aircraft, the air pressure is controlled by an air

pressure regulator (fig. 7-9). This regulator normally

maintains 40 psi pressure in the reservoir. It also

incorporates a relief valve to relieve excessive

pressure and a differential valve to allow equalization

Figure 7-9.—Air pressure regulator.

7-10