valve (B). Thus, a pressure stroke is produced with

each stroke of the pump handle.

Hand pumps are examined frequently for leakage,

general condition, and efficiency in operation. To

check the operation of a hand pump, the following

procedure is recommended:

1. Connect a direct-reading hydraulic pressure

gauge into the emergency hand pump pressure line.

2. Insert and lock the hand pump handle in the

pump actuating socket.

3. Select an appropriate subsystem to operate, and

place its selector valve in an operating position.

4. Actuate the hand pump handle until the unit

being operated has completed its movement. Check

the pressure gauge for a drop in system pressure.

NOTE: Air in emergency systems will cause

the pump handle to spring rapidly to the

other end of the stroke.

5. If a pressure drop is indicated, check the system

for leakage before removing the pump for repair or

replacement.

6. Observe the hand pump handle for piston creep,

which indicates that the pump should be removed for

repair or replacement.

Removal, replacement, and operational check of

hand pumps should correspond to the procedures

recommended in the specific MIM.

Power-Driven Pumps

As previously mentioned, power pumps are

generally driven by the aircraft engine, but may also

be electric-motor driven. Power pumps are classified

according to the type of pumping action used, and

may be either the gear type or piston type. Power

pumps may be further classified as constant

displacement or variable displacement.

A constant displacement pump is one that

displaces or delivers a constant fluid output for any

rotational speed. For example, a pump might be

designed to deliver 3 gallons of fluid per minute at a

speed of 2,800 revolutions per minute. As long as it

runs at that speed, it will continue to deliver at that

rate, regardless of the pressure in the system. For

this reason, when the constant displacement pump is

used in a system, a pressure regulator or unloading

valve must also be incorporated. The pressure

regulator valve will maintain a set pressure in the

system by diverting excess pump flow back to the

reservoir. The unloading valve will divert all pump

flow back to the reservoir when the preset system

pressure is reached. This condition remains in effect

until further demand is placed on the system.

A variable displacement pump has a fluid output

that varies to meet the demand of the system. For

example, a pump might be designed to maintain

system pressure at 3,000 psi by varying its fluid

output from 0 to 7 gallons per minute. When this type

of pump is used, no external pressure regulator or

unloading valve is needed. This function is

incorporated in the pump and controls the pumping

action by maintaining a variable volume, at near

constant pressure, to meet the hydraulic system

demands.

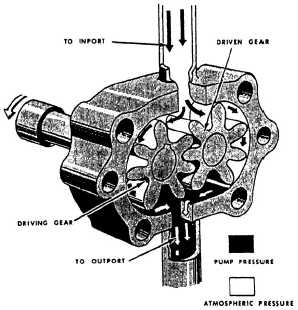

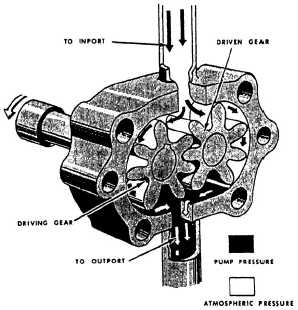

GEAR-TYPE PUMP.—A gear-type pump consists

of two meshed gears that revolve in a housing (fig. 7-

14). The drive gear in the installation is turned by a

drive shaft that engages an electric motor. The

clearance between the gear teeth as they mesh and

between the teeth and pump housing is very small.

The inlet port is connected to the reservoir line,

and the outlet port is connected to the pressure line.

In the illustration, the drive gear is turning in a

counterclockwise direction, and the driven (idle) gear

is turning in a clockwise direction. As the teeth pass

the inlet port, fluid is trapped between the teeth and

the housing. This fluid is carried around the housing

to the outlet port. As the teeth mesh again, the fluid

Figure 7-14.—Gear-type power pump.

7-14