between the teeth is displaced into the outlet port.

This action produces a positive flow of fluid under

pressure into the pressure line. A shear pin or shear

section that will break under excessive loads is

incorporated in the drive shaft. This is to protect the

engine accessory drive if pump failure is caused by

excessive load or jamming of parts.

All gear-type pumps are constant displacement

pumps.

These pumps are usually driven by a dc

wound electric motor. For those aircraft using

batteries, the pump may be used to build up hydraulic

pressure for the brake system during towing

operation.

Maintenance of a pump at the organizational level

consists of replacement of the complete assembly.

The motor and pump may be ordered separately;

however, this is normally done by intermediate- and

depot-level maintenance only.

Removal and installation procedures are found in

the applicable MIM.

The following removal

procedures are typical examples.

1.

2.

3.

4.

5.

6.

Relieve reservoir pressure.

Pull the pump circuit breaker and place a

warning card, DO NOT OPERATE, on the

pump switch.

Disconnect the pump motor electrical

connection at the motor.

Drain the pump reservoir or cap the reservoir

suction line.

Disconnect the drain line at the pump.

Loosen the pressure and suction lines “B”

nuts.

7.

8.

9.

Remove the mounting screws/bolts that secure

the pump assembly to the aircraft structure.

Disconnect completely the pressure and

reservoir suction lines at the pump.

Cap all open lines, and lift the pump assembly

out of the aircraft.

The following installation procedures are typical

examples:

1.

2.

3.

4.

5.

6.

Place the pump on the aircraft structure

mounting pad.

Connect the pressure and

suction lines to the pump ports and tighten the

“B” nuts fingertight.

Align and install the mounting screws/bolts.

Tighten the “B” nuts to the correct torque

values.

Attach the electrical connection to the motor.

Service the reservoir to the proper level.

Perform operational check according to the

applicable MIM.

NOTE: Prior to the installation of hydraulic

units, the preservation fluid must be drained

and the unit flushed with clean hydraulic

fluid.

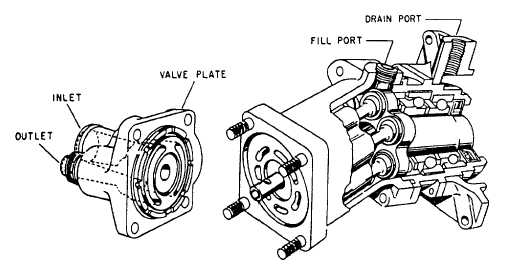

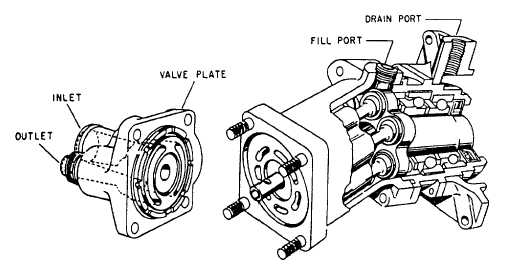

PISTON-TYPE PUMP (CONSTANT DIS-

PLACEMENT).—Piston-type constant displace-

ment pumps consist of a circular cylinder block with

either seven or nine equally spaced pistons. Figure

7-15 is a partial cutaway view of a seven-piston pump

manufactured by Vickers, Incorporated.

Figure 7-15.—Partial cutaway view of piston-type pump.

7-15