maintained flush with the wing. When the flaperon

pop-up cylinder is actuated, the gearing mechanism

transmits pop-up motion to each wing flaperon power

actuator.

The semiautomatic flaperon pop-up device aids in

reducing ground roll during landing.

The pop-up

system is activated by the pilot placing the flaperon

pop-up switch in the ARM position. All flaperons

(four) will then automatically pop up approximately

41 degrees when the aircraft weight is on the landing

gear and the throttles are retarded.

A mechanical interlock device prevents damage

to the flaperons during folding of the wings. When

the wings are folding, the flaperons cannot be

extended. In addition, the folding operation cannot

start unless the flaperons are flush with the wings.

A wing-fold interlock prevents flaperon pop-up

after the wings are folded. A fail-safe spring returns

the flaperons to the flush position in case the

combined hydraulic system or electrical system

should fail.

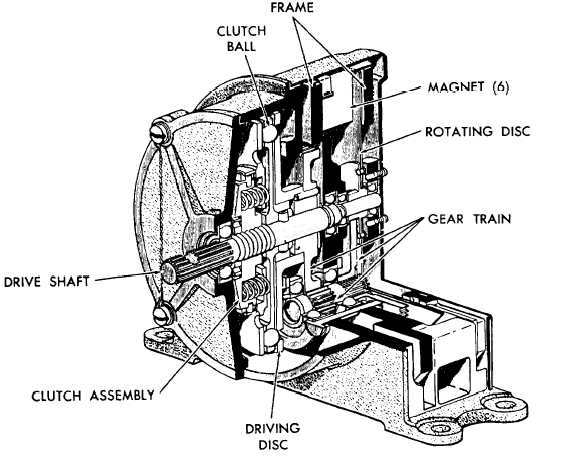

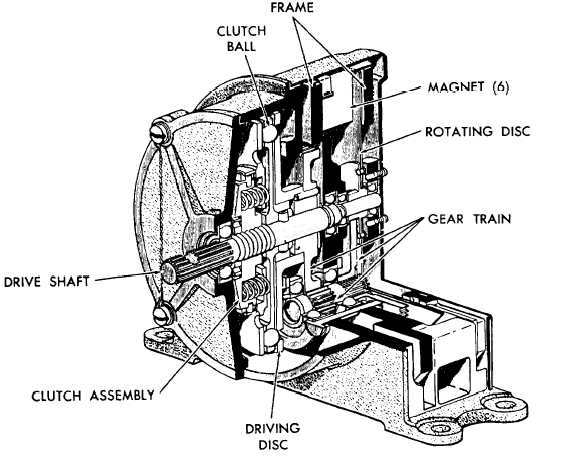

The eddy current damper links mechanically to a

bell crank in the flaperon control linkage. See

figure 9-11. It dampens any rapid left or right control

stick movement by producing an opposing force

proportional to the speed at which the stick is moved.

The damper contains permanent magnets, a rotating

copper disc, a gear train, and a clutch assembly.

Control stick motion rotates the clutch and gear train,

which, in turn, rotates the copper disc. The copper

disc is sandwiched in the air gap between the six

permanent magnets and a flux plate. As the copper

disc revolves, the magnetic field between the magnets

and the flux plate is disturbed, causing an opposing

force (eddy currents) that tries to stop the disc. The

opposing force is proportional to the speed of the

rotating disc and to the speed of stick movement. The

clutch will slip at a force of 275 to 325 inch-pounds to

prevent control stick binding if the damper jams.

Figure 9-11.—Eddy current damper.

9-13